The main indexes of mold materials include service performance and process performance. For a mold, if the performance of the material is considered carelessly, a variety of mold materials may meet the requirements. Only by fully considering the service life of the mold, the difficulty of the manufacturing process, the cost of the mold and many other factors, can we choose the right mold material.

Service Performance of mold materials

When selecting the mold material, the service performance of the mold material must be considered first. Among the many use properties, the wear resistance, toughness, hardness and thermal hardness of the material are the most important.

1. Wear resistance

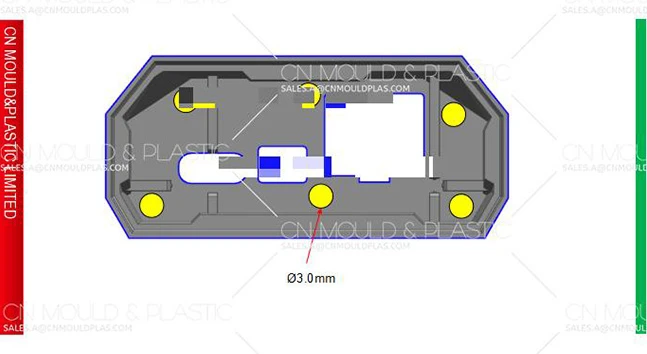

When the mold works, mold steel surface has strong frictions with plastic, in this case the mold must still be able to maintain its dimensional accuracy and surface roughness, that is, the mold material is required to have sufficient wear resistance. The wear resistance of the mold material is often an important factor in determining the service life of the mold.

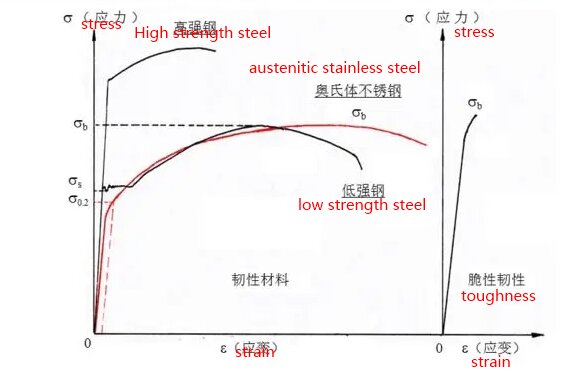

2. Toughness

For the mold subjected to strong impact load, its high temperature toughness at working temperature must be considered.

3. Hardness and thermal hardness

1) Hardness is the main technical performance index of the mold material, and the mold must have high hardness when working in order to maintain the original shape and size.

Generally, the hardness of cold-work die steel is about 60HRC, and the hardness of hot-work die steel is 45~50HRC, and the hot-work die steel is required to maintain a certain hardness at its working temperature.

2) Thermal hardness refers to the ability of a mold material to maintain its structure and hardness at a certain temperature. For hot-work die materials and some heavy load cold-work die materials, thermal hardness is an important performance index.

In addition to the above performance, we also need to respectively consider the actual requirements of the service performance. For example, for hot-work die steel, attention should be paid to its resistance to cold and thermal fatigue performance; For die-casting die, its resistance to melting metal erosion should be considered; The oxidation resistance of hot-work die at high temperature should be considered; For dies working in corrosive media, attention should be paid to their corrosion resistance; For dies working under heavy load, its compressive strength, tensile strength, bending strength, fatigue strength and fracture toughness should be considered.