In order to improve production efficiency and reduce costs, small plastic parts are often designed as multi-cavity molds. The Runner System in the injection mold refers to the flow channel of the plastic melt between the injection machine nozzle and the cavity, which is composed of sprue, runner, gate and cold-slug well. Its function is to evenly fill the plastic melt into each cavity in a smooth flow state, and in the process of filling and cooling, the injection pressure is transmitted to each part of the cavity.

The multi-cavity mold must have multiple runners to supply the molten material to each cavity. Therefore, whether the design of Runner System is reasonable directly affects the quality of injection parts, material consumption, production efficiency and production cost. The runner balance of the Runner System ensures that the quality, performance and other indicators of each cavity plastic parts are uniform. The runner balance means that the plastic hot melt can reach and fill the cavity with the same time, pressure and temperature. Therefore, the study of Runner System balance is very important.

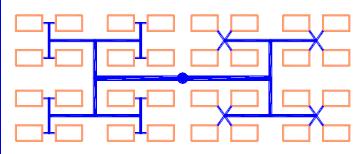

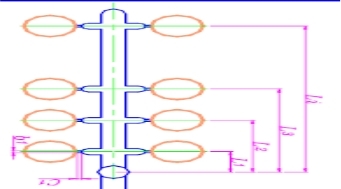

The arrangement of cavity and runner can be divided into two categories: balanced type and non-balanced type.

Balanced layout: The balanced layout is characterized by the same length, shape and section size of the runner from the sprue to the gate of each cavity, which can achieve the purpose of uniform filling of each cavity.

Non-balanced layout: The non-balanced layout is characterized by the unequal length of the runner from the sprue to the gate of each cavity. However, this arrangement can significantly shorten the overall flow of melt in the Runner System, and the compact mold mechanism can reduce the heat loss and injection pressure loss during the filling process, which shortens the mold filling time of melt.

The balanced state of the Runner System means that the plastic melt can fill the cavity at the same time when molding, and the plastic parts with the same size and good performance can be obtained after injection molding. The balance of the Runner System is closely related to the arrangement of cavity and runner.

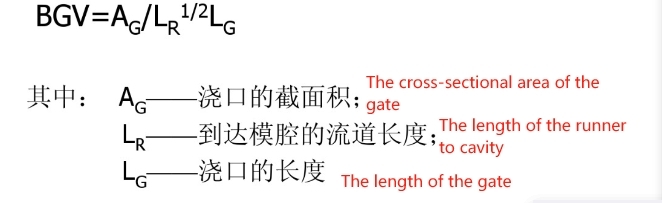

The balance of Runner System is often measured by the BGV value (gate balance value). If the BGV values calculated by each gate in the multi-cavity injection mold are equal, it means that the Runner System is basically balanced. On the contrary, the Runner System is unbalanced.

When using multi-cavity injection mold to process plastic parts, the balanced Runner System can improve product quality, reduce waste and defective products, and improve efficiency. The balanced layout of the cavity and the runner can meet the requirements of the balanced Runner System, but it will increase the complexity and cost of the mold. The non-balanced layout can also be adjusted by using the BGV value of the gate to meet the requirements of the balanced Runner System. This non-balanced Runner System is widely used in production practice due to the short length of runner and easy processing, but the size of each gate needs to be carefully adjusted, which add a lot more work to mold design and mold repair.

In short, by controlling the balance of the Runner System, the multi-cavity injection mold can make each cavity equally divide the required enough pressure from the total pressure through the Runner System, so as to ensure that the plastic melt is evenly filled with each cavity at the same time. Finally, the internal quality of the plastic parts in each cavity is uniform and stable.