There are many kinds of injection molding products, and the molds used by factories in production are also various and frequently changed. During the use and preservation of the mold, it must be maintained and protected to prevent damage, rust and other problems. The maintenance measures of the mold in the production mainly have the following aspects.

1.Every mold should have a history profile.

In the production, every tool should have a history profile to record its use, wear, damage and molding process parameters in detail. According to the situation recorded on the history profile of the mold, it can be found whether the parts are damaged and the size of the degree of wear, so as to provide information to find and solve the problem, which can shorten the mold trial time and improve efficiency.

2. Inspect and track important parts such as mold ejection parts, cooling systems, heating and control systems.

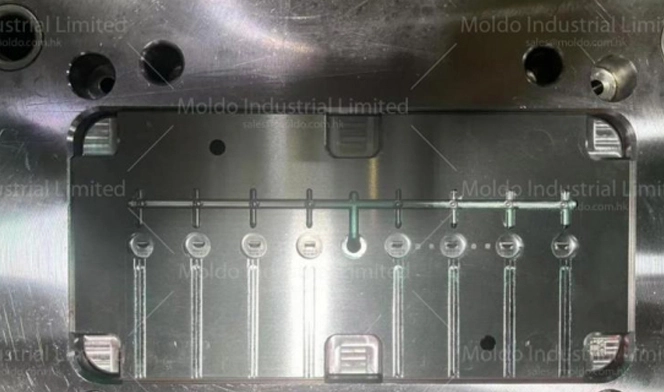

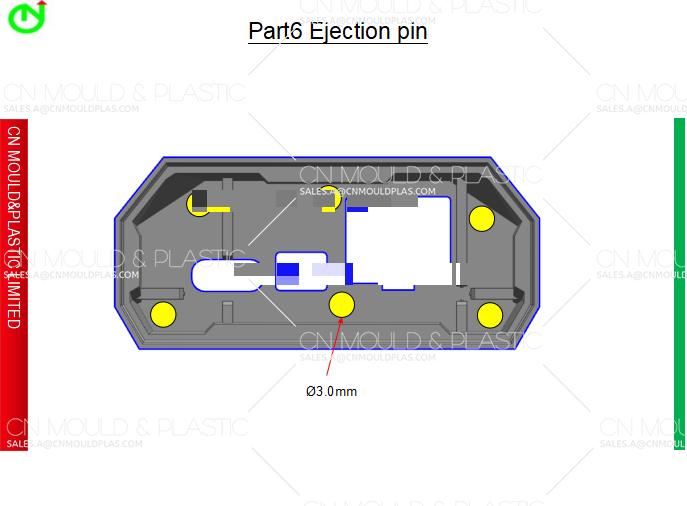

1) Pay attention to the maintenance of ejection pin and guide pin.

The ejection part of the mold ensures the opening and clamping movement of the mold and the smooth ejection of the plastic parts. Any part that is damaged will cause production to stop. Therefore, the ejection pin and guide pin should be regularly checked for deformation and damage. Once the problem is found, it should be replaced immediately. After the completion of a production cycle, the moving and guiding parts should be coated with anti-rust oil.

2) Cleaning and maintenance of the cooling water channel.

During production, the cooling water channel of the mold cooling system will become rusty, making the section of the cooling water channel smaller, and even blocked. Therefore, the heat exchange between the cooling water and the mold is greatly reduced. It is necessary to do cleaning and maintenance of the cooling water channel.

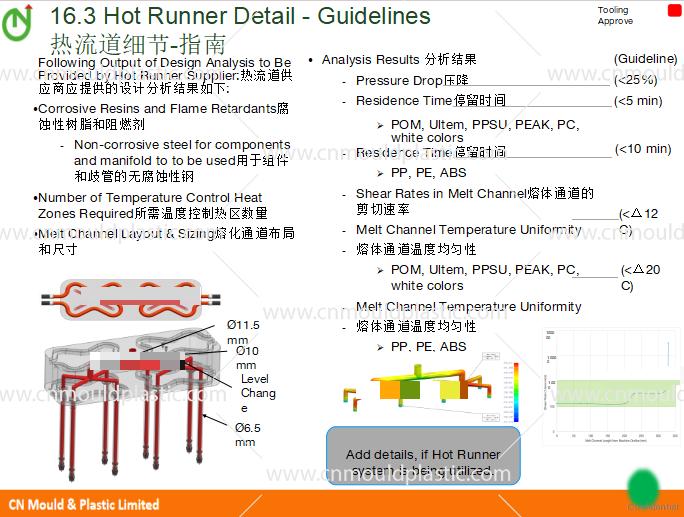

3) Strengthen heating and control system maintenance for hot runner molds.

For hot runner molds, the maintenance of heating and control systems should be paid with particular attention in order to prevent production failures. Therefore, after the end of each production cycle, every components should be checked. If there is damage, it should be replaced immediately, and carefully recorded in the mold history profile.

4) Pay attention to the maintenance of the mold surface.

The surface quality of the mold directly affects the surface quality of the product, therefore, the maintenance of the mold surface should be paid with particular attention. One of the most important things is to prevent corrosion. After the mold completes production, the cavity should be cleaned while hot. It is forbidden to use hard objects such as steel wire to clean the mold cavity in order to avoid scratching. Rust spots caused by corrosive resin, a grinding machine should be used to polish. Furthermore, we should apply an appropriate amount of anti-rust oil, and then place the mold in a dry and cool place.