The maintenance of injection molding machine is very important. Only by doing a good job of maintenance can we ensure the performance and service life of the injection molding machine. For the operator, it is also necessary to strictly abide by the operating procedures and work safely to ensure the safety and stable work of the machine. Here are some common maintenance methods:

1) Keep the machine clean

In the process of use, the injection molding machine will produce a large number of plastic debris, lubricating oil and other impurities. The operator should clean the residue of the machine surface and mold in time to keep the machine clean. Because these impurities will affect the accuracy and speed of the machine.

2) Change the lubricating oil regularly

Check regularly whether the lubricating oil of the injection molding machine needs to be replaced. In general, lubricating oil will gradually deteriorate over time and reduce its lubrication effect. Therefore, if there is a problem with the oil quality, the lubricating oil should be replaced in time.

3) Check the temperature control equipment regularly

The injection molding machine needs to maintain a certain temperature during the production process. Therefore, it is necessary to check and calibrate the temperature control equipment regularly to ensure its accuracy. If there are problems such as temperature instability, they should be eliminated in time.

4) Check the transmission system

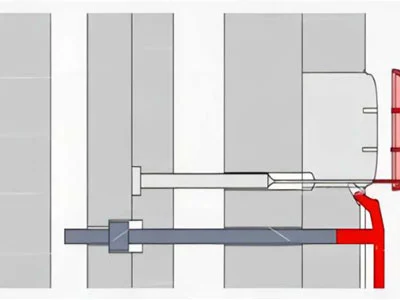

The transmission system of injection molding machine is a very critical part. Because it is directly related to the accuracy and efficiency of the machine. Therefore, it is necessary to check the parts of the transmission system regularly to ensure that they are in good working condition.

5) Replace vulnerable parts

The vulnerable parts of the injection molding machine include the nozzle, handle switch, power cable and so on. These parts can become worn or aged after prolonged use. Therefore, these vulnerable parts need to be replaced regularly.

6) Check the electrical system of the machine regularly

The electrical system of the injection molding machine is also an important part. Wiring, cables, power lines, etc. of the electrical system should be checked regularly, and safe operating procedures should be followed to prevent electrical failures.

1) Injection molding machine is difficult to start

When the injection molding machine is difficult to start, it is first necessary to check whether the power cord, power socket and fuse are normal. Secondly, check whether the controller of the injection molding machine is displayed normally, and if it is abnormal, the fault needs to be removed.

2) The temperature of the machine is uneven

When the temperature of the injection molding machine is not uniform, you can check whether the temperature control instrument and the heat exchanger are normal. These parts usually need to be repaired or replaced to make the temperature of the injection molding machine more stable.