Plastic residue refers to the plastic material sticked to the surface of the mold during the injection molding process, resulting in the surface of the product is not smooth, rough and uneven defects. This has a negative impact on the service life of the mold and product quality.

1. The main reason of plastic residue

1) The injection molding process is not reasonable. Improper parameters of the injection molding process such as too long injection cycle and too short injection time of the injection molding parts, results in the injection molding parts sticking to the mold surface.

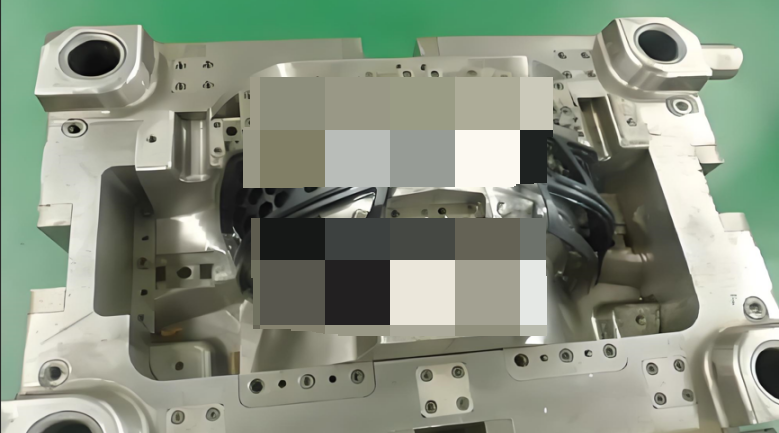

2) Poor mold quality. The surface of the mold is rough and scratched. The surface of the mold is not polished or the service life is too long may lead to plastic residue.

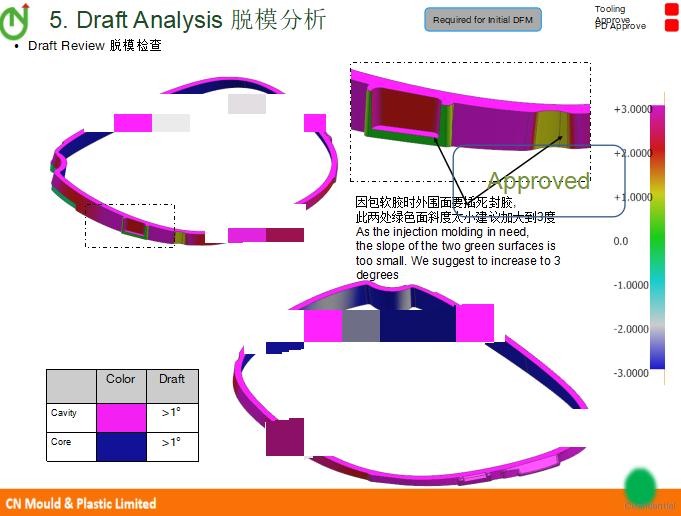

3) Inappropriate draft angle. Insufficient draft angle can also cause plastic residue.

4) Mold temperature is not suitable. Mold temperature is too low or too high will lead to plastic residue. If the mold temperature is too low, it will lead to slow material flow. If the mold temperature is too high, it will lead to mold surface oxidation and increase the coefficient of friction, resulting in plastic residue.

2. The solution

1) Improve the surface quality of the mold or apply an anti-stick coating to the mold surface.

2) Increase appropriately the draft angle, and it is best to ensure that the draft angle is between 3° and 5°

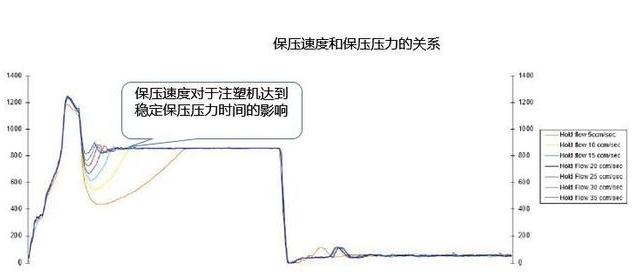

3) Properly reduce the injection pressure and holding pressure. If the pressure is too large after injection molding, it will also cause plastic sticked on the wall of the mold.

4) Select the release agent suitable for the specific mold and plastic material. Coating a layer of anti-sticking agent on the surface of the mold can play a role in reducing the friction coefficient of the mold surface and reducing the phenomenon of stick mold.

5) Control the mold temperature and adjust the mold temperature through the cooling system.