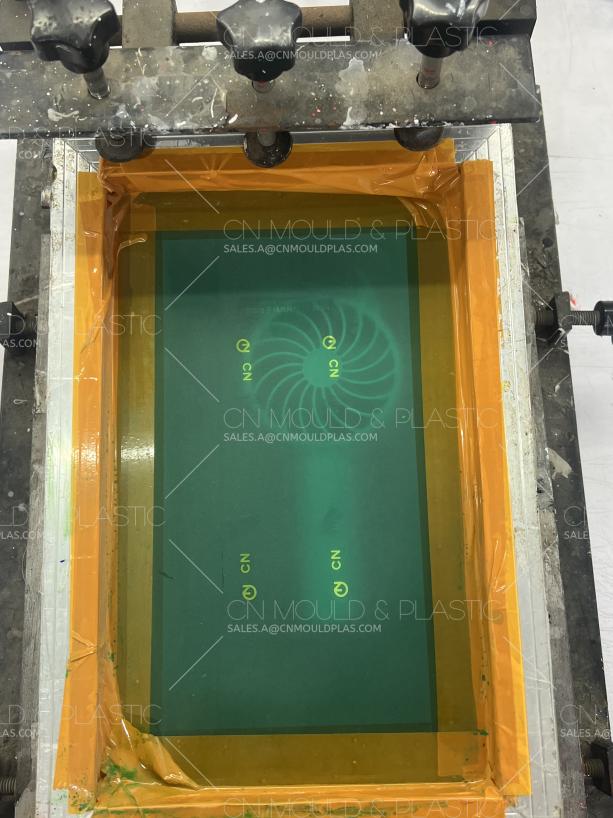

Screen printing is a printing method by which ink is transferred to the surface of the substrate through a screen plate. Its core part is a printing plate made of silk screen, forming a hole pattern in the layout, so that ink can only be transferred to the substrate through these holes. During the printing process, the scraper exerts a certain pressure along the screen plate, so that the ink is extruded from the hole to the substrate surface, so as to realize the decoration and protection of the material surface.

1) Printing preparation: select the appropriate substrate material, such as paper, plastic, metal, etc. Select the appropriate size of the screen plate according to the need; Prepare the necessary ink and auxiliary tools.

2) Plate making: Using film to make a negative or positive film, place it above the screen, and cure it through ultraviolet exposure. The uncured part is then elution to obtain a screen plate with a pattern.

3) Printing: Adjust the Angle, speed and pressure of the scraper to ensure that the ink is fully transferred to the surface of the substrate to complete the monochrome or multi-color overprinting operation.

4) Drying: the printed substrate is sent to the oven or dried naturally, and the finished product is ready after the ink is dried.

5) Cleaning and maintenance: clean the screen plate and equipment, keep the working environment clean, in order to facilitate the smooth development of the next printing task.

The mold cost is low, but it still depends on the number of colors, because each color must be made separately. Labor costs are high, especially when it comes to multi-color printing.

light-colored screen printing inks have less impact on the environment, but inks containing PVC and formaldehyde have harmful chemicals, which need to be recycled and treated in time to prevent pollution of water resources.

Screen printing can be done on almost any material, including paper, plastic, metal, pottery, and glass.

Screen printing has been widely used in many fields because of its ability to achieve fine images, high weather resistance and printability. Common prints are: plastic parts, oil paintings, posters, business cards, bound covers, product signs and so on.