Low-pressure molding technology as an important link in modern industrial production, its production efficiency is directly related to the economic benefits of enterprises and market competitiveness. Therefore, improving the production efficiency of low-pressure molding has become the focus of attention of enterprises. In this paper, we will optimize process parameters, improve equipment performance and enhance the level of automation in three aspects, to discuss how to improve the production efficiency of low-pressure molding.

The cost of low-pressure molding technology mainly includes raw material costs, equipment depreciation and maintenance costs, labor costs, and energy costs. Raw material costs are the most direct expenses in the low-pressure molding process, and their prices are affected by a variety of factors such as market supply and demand, raw material quality, and procurement strategies. Equipment depreciation and maintenance costs are closely related to the investment scale, service life, and maintenance of the equipment. Labor costs are related to the salary, training, and welfare of employees, which is an important expense to ensure the smooth operation of production. Energy costs include power, water, and other production energy consumption costs.

Optimization of process parameters is the key to improve the productivity of low-pressure molding. First of all, we should reasonably set the molding temperature, pressure, and time and other parameters to ensure that the plastic material in the mold can flow evenly and fully cured. Through tests and data analysis, find the best combination of process parameters to improve product molding quality and production efficiency.

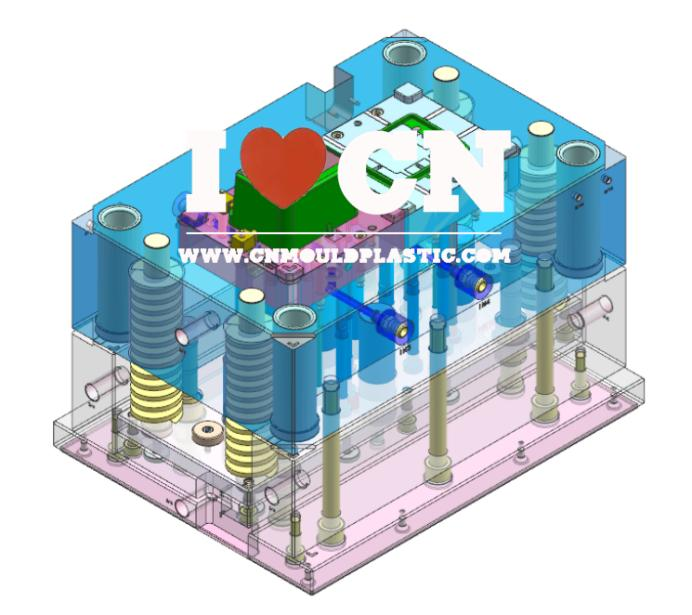

Secondly, pay attention to the design and manufacturing quality of the mold. Whether the structure of the mold is reasonable or not directly affects the molding efficiency and product quality. Therefore, when designing the mold, we should give full consideration to the shape, size, and precision requirements of the product, optimize the runner design and exhaust system of the mold, reduce the resistance of plastic flow in the mold, and improve the filling speed and uniformity.

The performance of the equipment has an important impact on the productivity of low pressure molding. First of all, choose stable performance, easy-to-operate molding equipment to ensure that the equipment in the production process can run stably, and reduce the failure rate and downtime.

Secondly, to strengthen the maintenance and repair of equipment. Regular overhaul and maintenance of equipment, timely detection and resolution of potential problems, to extend the service life of the equipment. At the same time, it is necessary to do a good job of cleaning the equipment, keep the equipment clean and tidy, and avoid the interference of dust and impurities on the production.

The application of automation technology is an important means to improve the production efficiency of low-pressure molding. First of all, automated production lines and robotics can be introduced to realize the automated operation of the molding process, reduce manual intervention and labor intensity, and improve production efficiency and quality stability. Secondly, Internet of Things and big data technology can be used to realize real-time monitoring and data analysis of the production process. Through the collection and analysis of production data, problems in the production process can be found and adjusted in time to optimize the production process and improve production efficiency.

In summary, improving the productivity of low-pressure molding needs to start from many aspects, including optimizing process parameters, improving equipment performance, enhancing automation level, and strengthening employee training. Only by comprehensively considering these factors and taking effective measures can we realize the continuous improvement of low-pressure molding production efficiency and contribute to the sustainable development of the enterprise.