From anti-vibration to isolation, dual-shot injection technology has greatly improved today's product performance. It helps the products to achieve soft touch, robust support and durability requirements at the same time. Yet, not every mould-maker can manage bunches of problems that over-moulding brings in. BELOW is an example of dual-shot mould coordination. It shows how CN's mould designers think out of the box and solve the problem by modifying standard mould structure.

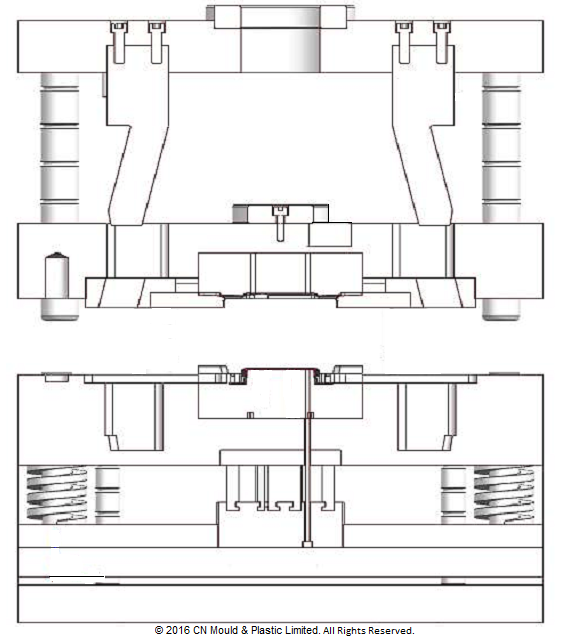

Mould 1

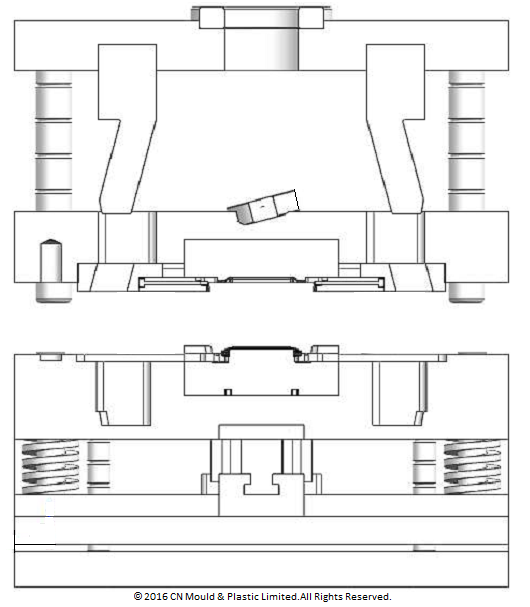

Mould 2

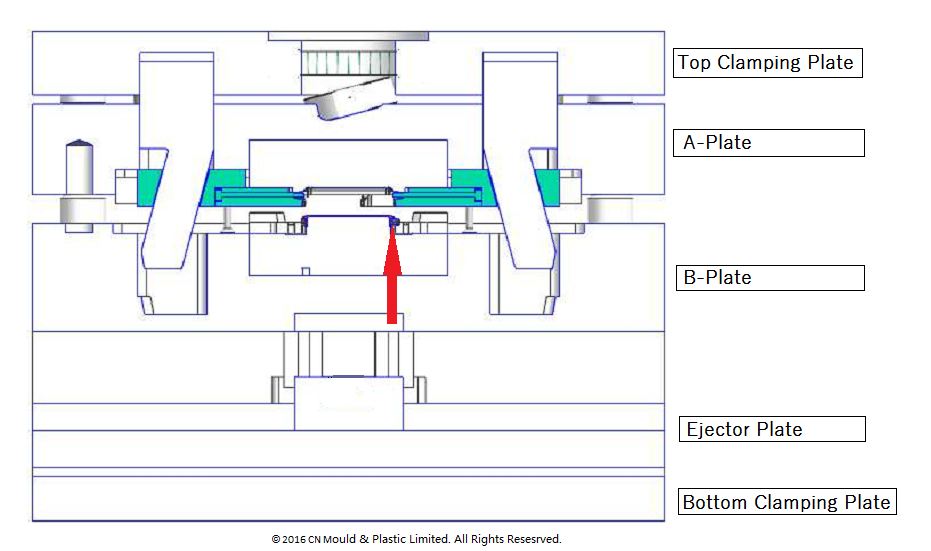

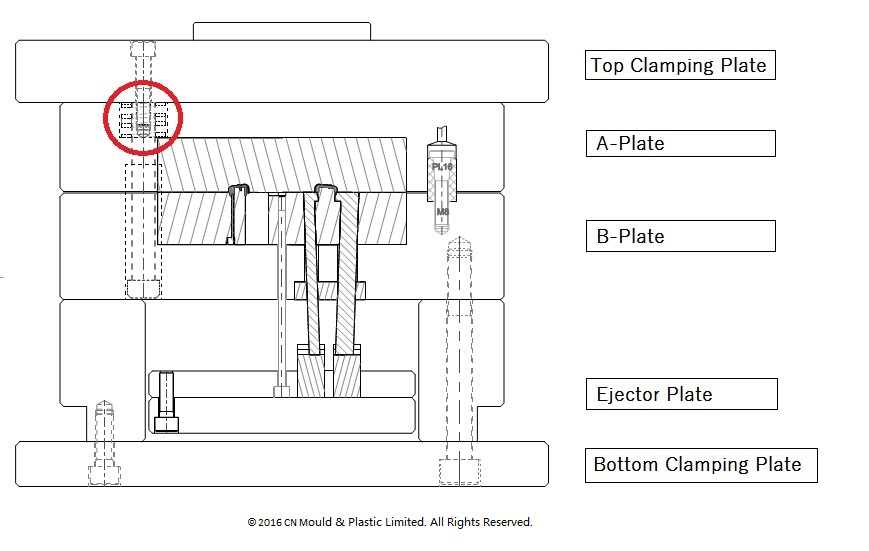

Unlike conventional moulds, the angle pin and the slides are installed on Top Clamping Plate and A-Plate respectively. When the first shot is finished, two B-Plate switches for the next shot to mould another material.

Clearly, during mould closing, it is not predictable whether Top Clamping Plate close fully before A-Plate and B-Plate or the other way round. In the figure above, Top Clamping Plate and A-Plate close quicker. If the mould keep closing, the slides (light green) will collide with the part made in Mould 1 previously (pointing by red arrow). Thus, the problem occurs. How could we prevent the clash?

Add a spring between Top Clamping Plate and A Plate. When the mould is closing, the spring will resist clamping force to force A-Plate and B-Plate close first. Simple and Easy. :)

A designer cannot solve problems without creative thinking and experience. A company cannot survive without creative and experienced experts. An industry will die out without innovative companies. Manufacturing industry is becoming more and more competitive. We live with reasonable pricing offer and solution-oriented capability.Please let us know your need and our expert would bring delightful contribution to your product.