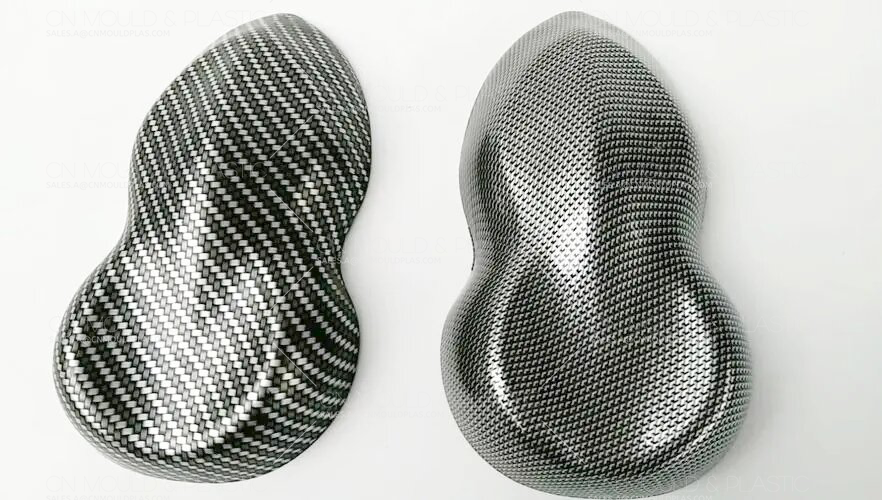

Hydro Transfer Printing is a technology that uses water as a medium to paste the text onto the surface of the product through an intermediate carrier (special paper or plastic film). It is a way of using water pressure to print the color pattern of the transfer paper on the surface of the three-dimensional product. As people's requirements for product packaging and surface decoration increase, the use of Hydro Transfer Printing is more and more extensive. Hydro Transfer Printing can not only be applied to a variety of daily necessities, such as mobile phone cases, auto parts, motorcycle shells, etc., but also can be applied to aerospace, medical equipment and other high-tech fields.

All hard materials are suitable for Hydro Transfer Printing, and materials suitable for spraying must also be suitable for Hydro Transfer Printing. The most common applicable materials are injection molded parts and metal parts. Some materials in plastic have better printing performance, such as ABS, PC, PET, etc., which can be transferred without coating. However, PS is more difficult to complete Hydro Transfer Printing , because it is very badly corroded by the solvent. And the active component of the activator is easy to cause serious damage to PS, so the transfer effect is relatively poor. Non-absorbent materials such as glass, metal, ceramics, non-polar materials such as PE, PP and some PVC materials require a special coating for Hydro Transfer Printing. Coating is a variety of paints that have good adhesion to special materials. From a printing point of view, coating technology realizes the possibility of decorating the surface of many materials that cannot be printed.

There is no mold cost, but it is necessary to use fixtures to complete Hydro Transfer Printing of multiple products at the same time, and the time cost is generally not more than 10 minutes per cycle.

Hydro Transfer Printing applies printing coatings more fully than product spraying, reducing the possibility of waste leakage and material waste.

l Advantages of Hydro Transfer Printing:

1) Bright colors: Hydro Transfer Printing can achieve high-definition pattern printing, the pattern of bright colors, high clarity, and no color difference.

2. Wide range of application:Hydro Transfer Printing technology can be applied to surface printing of various materials, such as plastics, metals, ceramics, etc.

3. Easy to operate: Hydro Transfer Printing is easy to operate, and only simple machines and equipment are needed to achieve high-quality printing results.

4. Low cost: compared with traditional printing technology, Hydro Transfer Printing has low cost and can be mass-produced to improve production efficiency.