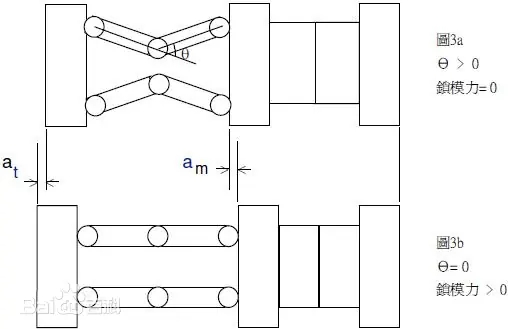

Clamping force refers to the locking force applied to the mold by the injection machine to overcome the expansion force of the melt in the mold cavity during injection. When the raw material is injected into the cavity at high pressure, plastic pressure will generate against mold wall, so the mold clamping unit of the injection molding machine must provide enough "mold clamping force" to prevent the mold from being stretched open.

Calculation of mold clamping force

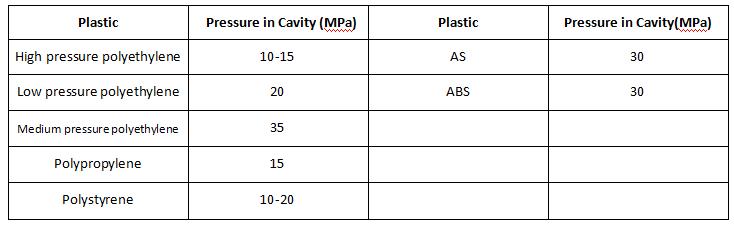

A: The required clamping force is related to the mold structure, mold cavity pressure and product size.

Clamping force(MPa) = the average pressure in the mold cavity(the general product can be 30MPa) x the safety factor(generally is 1.1~1.2) x the projected area of the product on the parting surface x cavity number.

B: How to choose the right injection molding machine: 1MPa=9.8kg/cm².

Selection of injection molding machine

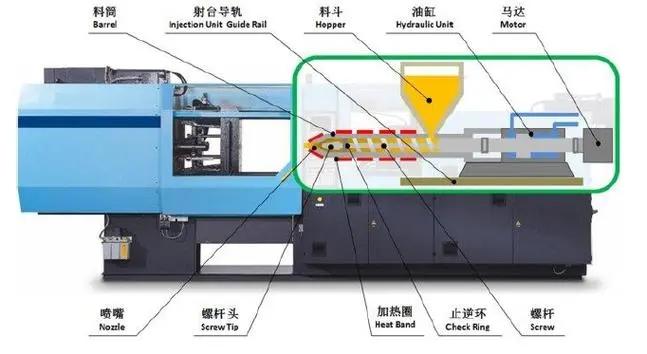

1. Choose the right type

The type and series of injection molding machines are determined by the products and plastics. Since there are many types of injection molding machines, it is necessary to correctly determine which kind of injection molding machine should be produced at the beginning. In addition, some products require high stability, high precision, ultra-high injection speed, high pressure or fast production conditions, so we must choose the right series to produce.

2. The mold can be put into the machine

1) The width and height of the mold should be less than or at least one side is less than the large tie bar inner space.

2) The width and height of the die are best within the size range of the clamp platen.

3) The width and height of the mold should meet the minimum mold size recommended by the injection molding machine.

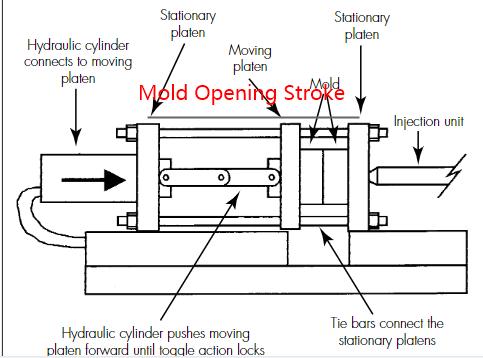

3. Meet the requirement of ejection

Determine from the mold and finished product whether the mold opening stroke is sufficient for the finished product to be removed. The mold opening stroke refers to the distance between the two platen of the injection molding machine, and the size of it directly affects the size of the mold of injection molding. The purpose of the mold opening stroke is to ensure that the mold can be fully opened to facilitate the removal of the product.

4. Enough clamping force

By the product and plastic to determine the clamping force tonnage. The mold clamping force requirements are calculated as follows:

The clamping force of the machine must be greater than the force exerted by plastic injection into the cavity to hold the mold apart, and for the sake of security, the clamping force of the machine usually needs to be more than 1.17 times the holding force.

The force exerted by plastic injection into the cavity to “open the mold” = projected area of the finished product (cm2)× number of cavity × pressure in the mold (kg/cm2);

The pressure in the mold varies with the raw material, and the general raw material is 350~400kg/cm2