In the field of injection molding, the design of the cooling system is of paramount importance. This is because plastic parts must be cooled and solidified to a certain degree of rigidity before they can be ejected from the mold without deforming due to external forces.

Cooling time accounts for approximately 70% to 80% of the entire molding cycle. Therefore, a well-designed cooling system can significantly shorten the cycle time, increase injection production rate, and reduce costs. On the other hand, a poorly designed cooling system can lead to longer cycle times, increased costs, and uneven cooling, which can further cause warping and deformation of the plastic parts.

According to experiments, the heat generated by the molten plastic entering the mold is dissipated in two main ways:

1. Radiation and convection: Approximately 5% of the heat is transferred to the atmosphere through radiation and convection.

2. Conduction: The remaining 95% of the heat is transferred from the molten plastic to the mold through conduction.

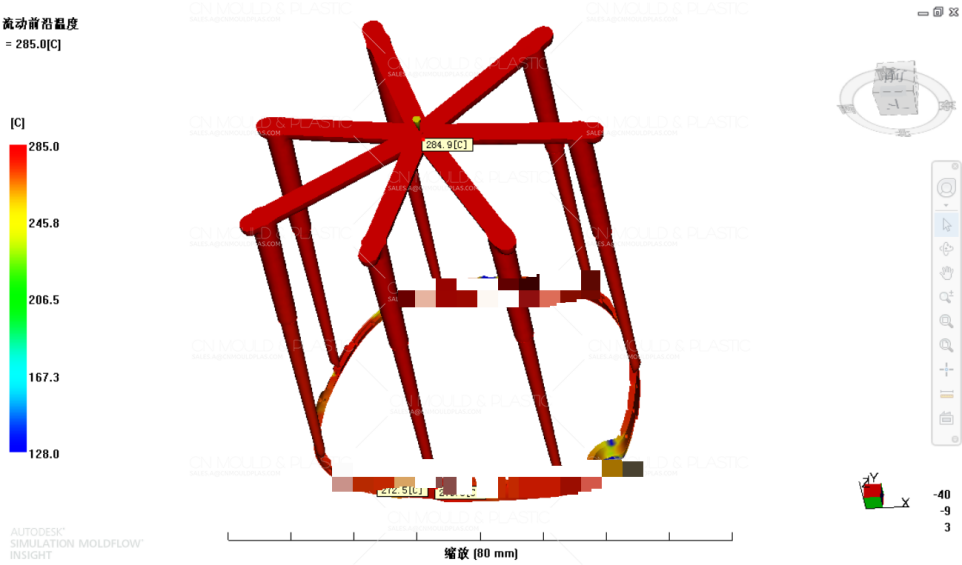

In the mold, the heat is transferred from the plastic in the mold cavity to the cooling water pipes. The heat is then carried away by the cooling liquid through heat convection. The small amount of heat that is not carried away by the cooling water continues to be conducted in the mold until it reaches the outside surface and is dissipated into the air.

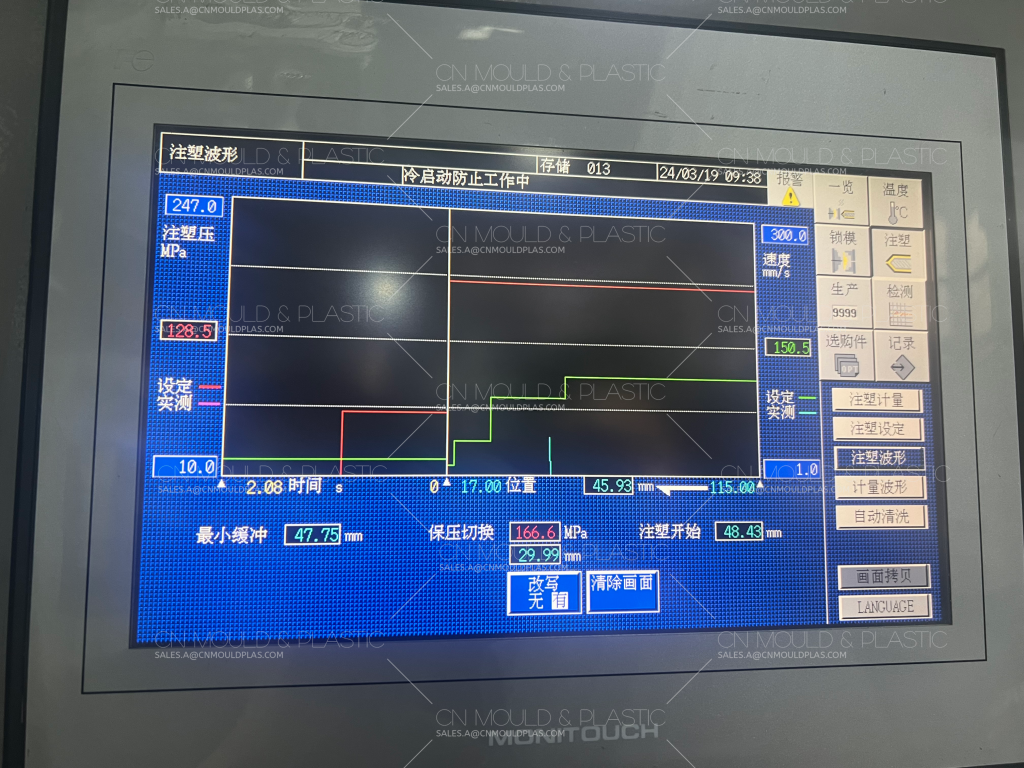

The molding cycle time is composed of the following stages:

1.Clamping time

2.Filling time

3.Holding pressure time

4.Cooling time

5. Ejection time

In these stages, the cooling time has the largest proportion, accounting for approximately 70% to 80%. Therefore, cooling time directly affects the length of the molding cycle and the production speed.

The plastic parts must be cooled to a temperature below their heat deflection temperature before they can be ejected from the mold. This prevents the parts from deforming due to residual stress relaxation or external forces during ejection.

The design of the cooling system is a critical factor in the success of injection molding. By understanding the principles of heat transfer and the impact of cooling time on the molding cycle, manufacturers can design and optimize their cooling systems to achieve high-quality, efficient, and cost-effective production.