As we all know, the mold locking system of the injection molding machine is very important to the injection molding machine. The following are common reasons for locking failure and how to effectively prevent it:

The slider is one of the key parts of mold locking in injection molding machine. When the slider is stuck, the mold cannot be locked normally. The cause of the slider sticking may be the wrong direction of the slider or the damage of the hydraulic cylinder.

The solution:

1) Keep regular maintenance to ensure that the surface of the slider is smooth and without scratches.

2) Check whether the direction of the slider is correct.

3) Check whether the hydraulic cylinder is damaged, and replace it if it is damaged.

Inaccurate mold position may also cause the injection molding machine to fail to lock the mold. The reason may be that the template is shifted and the positioning pin is loose, etc.

The solution:

1) Check whether the template is shifted. If yes, adjust it again.

2) Check whether the positioning pins are loose. If they are loose, reinforce or replace them.

Injection molding machine hydraulic system problems can also lead to mold locking failure.

It may be caused by hydraulic pipeline blockage, hydraulic oil missing or hydraulic motor failure.

The Solution:

1) Check whether the hydraulic pipeline is blocked, and clean the hydraulic pipeline if necessary.

2) Check whether the hydraulic oil is sufficient, if insufficient, it is necessary to add hydraulic oil in time.

3) Check whether the hydraulic motor is faulty. If there is a fault, replace it in time.

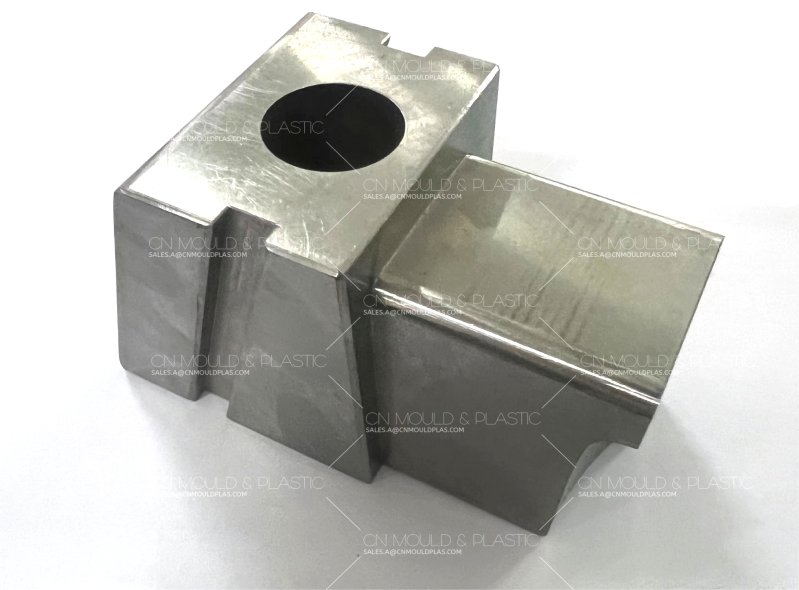

The mold may have problems such as inaccurate size or damage in the manufacturing process, resulting in the injection molding machine can not be locked normally.

The Solution:

1) Check and maintain the mold: check whether the mold is damaged or the size is inaccurate, repair or replace it in time.

2) Test and check before injection production to ensure that the mold is in good condition and can be used normally.

In short, mold locking failure is a common problem in the injection molding machines, which needs to be checked and eliminated according to the specific situation.

By taking effective measures to solve the problem of mold locking failure, the production efficiency and quality of injection molding machine can be improved, and the production of enterprises can be smoothly guaranteed.