Mold clamp failure of injection molding machine is one of the common problems. Here are some common mold clamp problems and how to solve them:

The solution:

1) check whether it is reverse hinge.

2) Check whether the mode-locking straightener terminates at zero position after stranding, and adjust the zero position of the electronic ruler

2. Clamping is not smooth

The solution:

1) Check the hydraulic circuit and the air in the oil circuit must be emptied. If there are bubbles in the oil also need to vent.

2) Holes A and B are improperly adjusted. When the system flow rate is 20 and the pressure is 99, observe whether the mode-locking action is working g after setting;

3) Check the magnifying plate. Adjust its position when you find it out of place.

The solution:

1) The starting speed is slow, check whether the screw damping is too large, and adjust the screw damping hole.

2) The middle hole of the damping screw is too large, check whether the damping of the Y-hole screw is too large, and change the damping nail with a fine center hole.

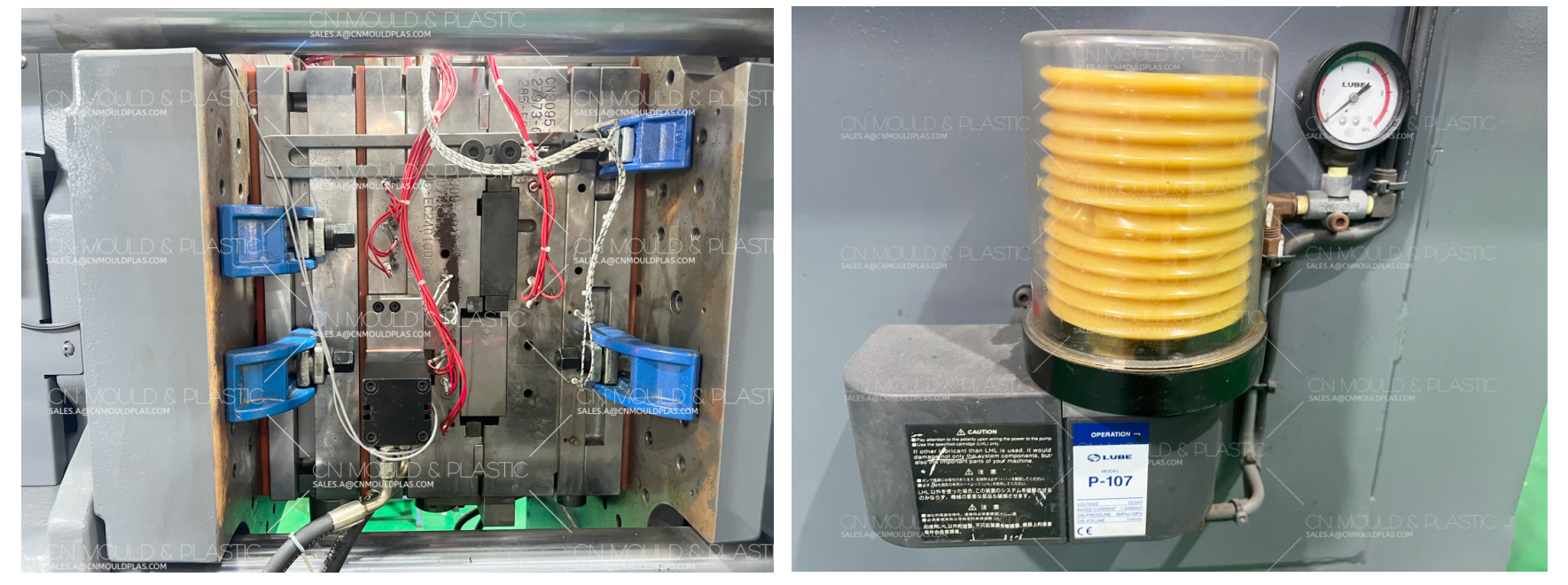

1) Check whether the lubricating oil pipe is disconnected, if it is, it must be re-connected.

2) The amount of lubricating oil is small, and the amount of lubricating oil should be increased.

3) The clamping force is large, check whether the mold needs large clamping force, and reduce the clamping force.

4) Check whether the current parameters meet the acceptance standards, and readjust the current value.

5) The parallelism is out of tolerance, check whether the parallelism is greater than the acceptance standard.