To enhance productivity, factories may operate nearly 24 hours a day. Assuming 25 operational days per month, the machine will accumulate 600 hours monthly and 7,200 hours annually. Since injection molding machines operate 4-5 times longer than general machinery, their maintenance must be prioritized to extend their service life.

Hydraulic Oil Volume Check

Ensure the oil level is above the minimum mark and below the maximum mark on the oil gauge.

Temperature Activation and Inspection

Verify the proper functioning of electrical heating devices on the dryer, barrel, and mold.

Safety Door and Emergency Stop Switch Check

Confirm the integrity of safety doors and emergency stop buttons.

Low-Pressure Mold Clamping Device Check

Ensure the low-pressure mold clamping device functions correctly to protect the mold.

Lubrication System Check

Check oil levels in oil cups and lubricators. Ensure lubrication pipelines are fully unobstructed.

Moving Parts Inspection

Adequately lubricate all moving components. Remove debris or dust from friction surfaces to maintain smooth operation. Avoid placing tools on moving parts.

Cooling Water Check

Inspect the cooling water system for leaks. Ensure sufficient water supply to maintain cooling efficiency.

Parameter Verification

Validate settings for temperature, pressure, speed, time, and distance.

Limit Switches and Cam Adjustment

Adjust and secure limit switches and impact cams, especially after mold changes.

No-Load Operation Test

Reduce injection pressure slightly, switch from manual to automatic mode, and run the machine without load for 10–30 minutes. Begin formal operation once stable conditions are achieved.

Abnormal Noise Detection

Record normal operational sounds. Unusual noises from hydraulic pumps may indicate filter blockage, air suction, or internal wear. Buzzing from solenoid valves or relays may signal contamination or poor contact.

Close the hopper gate and reduce/disable hopper heating (depending on shutdown duration).

Perform 1-2 additional injection cycles.

Turn off or reduce barrel heating (depending on shutdown duration).

Clean and rust-proof the mold (if shutdown is prolonged).

Shut off cooling water and power.

Clean the machine.

Electrical Heaters

Check for broken wires or loose connections.

Oil Leak Inspection

Identify even minor leaks.

Bolt Tightness Check

Inspect all machine bolts for looseness.

Nozzle Heater Check

Remove resin buildup on nozzle heaters or wires.

Waste Oil Removal

Clear accumulated waste oil.

Filter Cleaning

Clean oil filters every 2-3 weeks for the first six months, then every 2-3 months.

Full Machine Cleaning

Recheck weekly items with stricter standards.

Grounding Check

Inspect grounding wires and terminals to prevent electric shock risks.

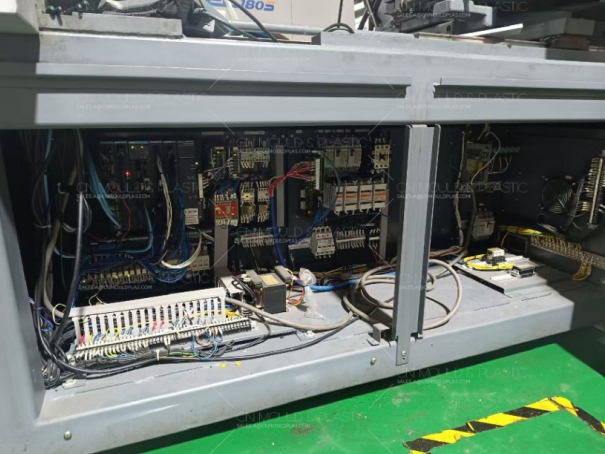

Electrical Circuit Check

Ensure relays are fully seated, contacts are clean, and terminal screws are tight.

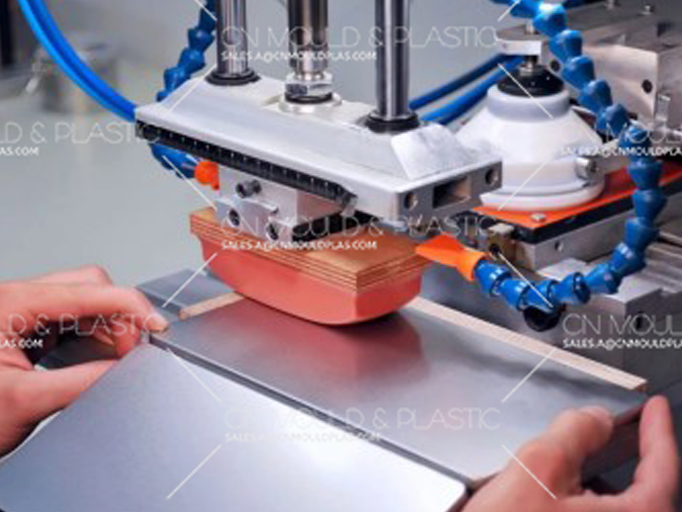

Moving Mold Base and Hydraulic Motor Slide Check

Inspect slides for wear and bolts for tightness.

Cooler Maintenance

Clean coolers monthly if using groundwater, industrial water, or brine. For treated water, clean every six months.

Recheck monthly items with enhanced rigor.

Hydraulic Oil Quality Test

Have oil suppliers conduct oil quality tests.

Wear Inspection

Check all moving parts for abnormal wear.

Recheck semi-annual items with heightened precision.

Electric Motor Maintenance

Clean motor cooling vents with a wire brush or compressed air to prevent overheating.

Ventilation System Check

Clear dust and oil from vents to avoid motor damage or oil temperature rise.

Insulation Resistance Test

Measure insulation resistance to prevent electrical leaks caused by aged wire coatings.

This structured maintenance plan ensures optimal performance, safety, and longevity of injection molding machines.