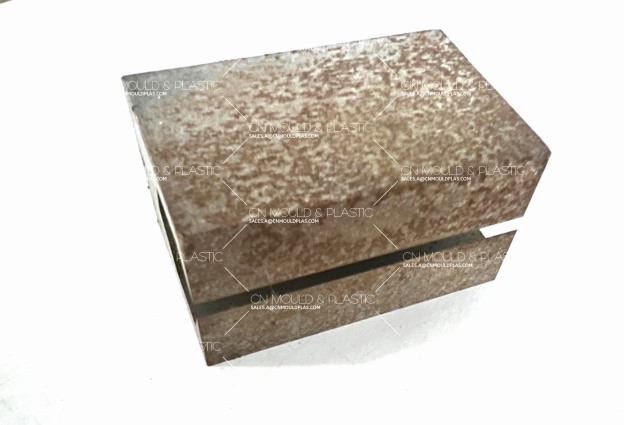

Metal is one of the most widely used materials in modern society. Their hardness is extraordinary, but they will inevitably be damaged, the most common are fracture, wear, corrosion, and corrosion is the most common phenomenon. Metal corrosion refers to the phenomenon of chemical or electrochemical interaction between metal and the surrounding environment (or medium) and is destroyed or deteriorated. Corrosion of metal materials will significantly reduce the performance of metal materials, destroy the geometry of metal components, and even cause catastrophic accidents such as fire and explosion. Therefore, it is necessary for us to study deeply how to effectively prevent metal corrosion.

According to the classification of corrosion forms, corrosion can be divided into two categories: general corrosion and localized corrosion.

1) General corrosion - Corrosion on the entire metal surface, also known as uniform corrosion. The result of corrosion is a reduction in the mass of the material and a thinning of the thickness. General corrosion is less harmful, because as long as the corrosion rate of the material is known, the service life of the material can be calculated. In most cases, the metal surface will form a protective corrosion product film, so that the corrosion slows down.

2) Localized corrosion - The corrosion of local areas of the metal surface is much greater than the rest of the surface, resulting in the formation of potholes, grooves, delamination, perforation, rupture and other damage patterns. Its harm is much more serious than general corrosion, accounting for more than 65% of the mechanical corrosion of equipment. Because most of the localized corrosion is difficult to find, the equipment will have sudden and catastrophic effects, which can induce fire, explosion and other accidents.

Generally speaking, the main types of local corrosion are galvanic corrosion, pitting corrosion, crevice

Corrosion, intergranular corrosion, stress corrosion cracking, weld corrosion, corrosion fatigue and selective corrosion.

(1) There is a large electrochemical heterogeneity in the metal, so that the anode and cathode regions can be clearly distinguished.

(2) The difference in electrochemical conditions between the anode region and the cathode region has been maintained during the corrosion process, so that the anode dissolution rate in some local areas has been maintained higher than the rest of the surface.This is the condition for localized corrosion to continue.

1) Corrosion morphology: The general corrosion is distributed on the entire metal surface, localized corrosion is mainly concentrated in a certain area, and other parts are not corroded.

2) Corroded battery: The anode and cathode of general corrosion change randomly on the surface and are not distinguishable. In localized corrosion, anode and cathode can be distinguished from each other on a macroscopic level.

3) Electrode area: The anode area of general corrosion is equal to the cathode area. The cathode area of localized corrosion is larger than the anode area.

4) Corrosion products: The products of general corrosion may have a protective effect on the metal. On the contrary, the situation corrosion has no protective effect.