Before the birth of 3D printing technology, the manufacturing industry around the world is based on molds as the main production.In the past few decades, the mold has made great contributions to the processing and manufacturing industry, so it is also called the "mother of industry ". In this era of rapid technological change, new technologies are always constantly impacting the traditional technical methods, and now the most popular 3D printing technology is the biggest challenge for the molds, although the challenger is not too mature. So what are the differences between 3D printing technology and traditional molds?

Manufacturing molding method

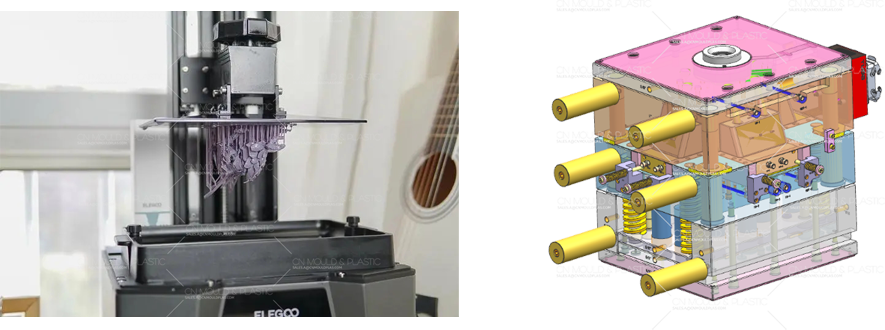

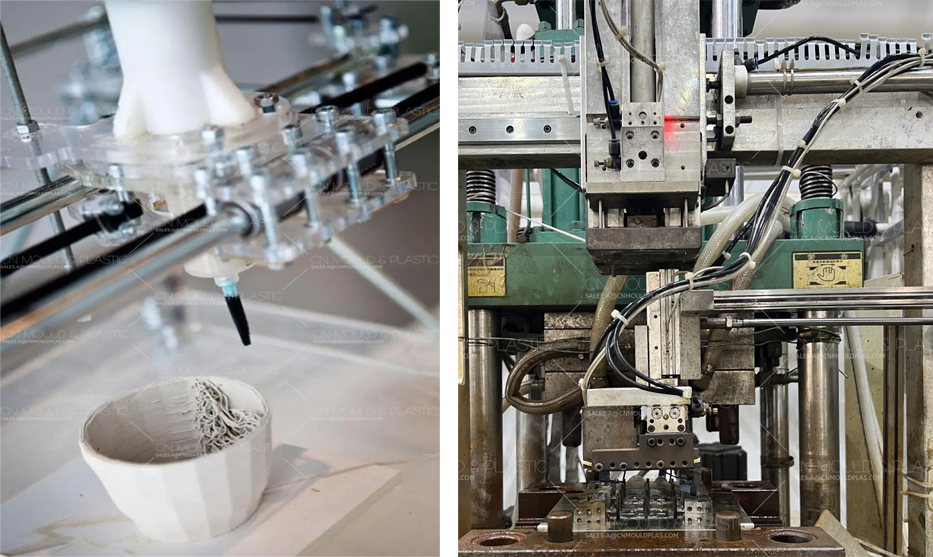

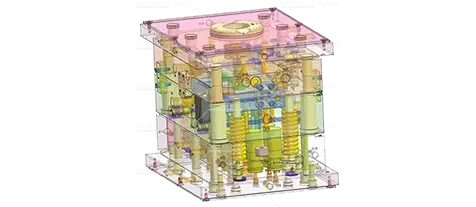

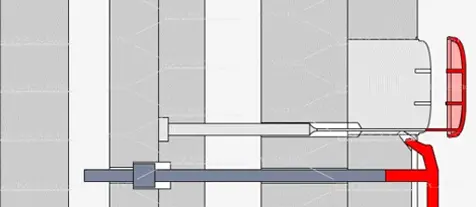

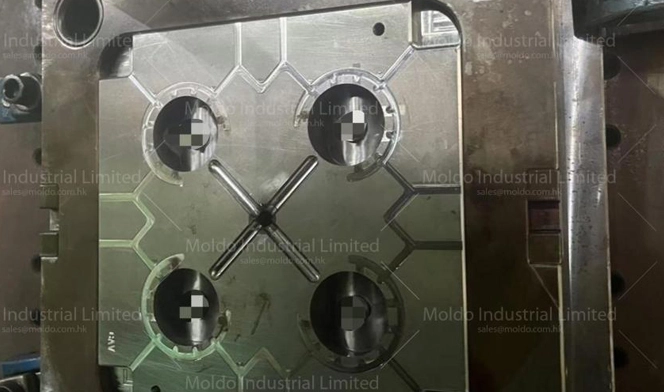

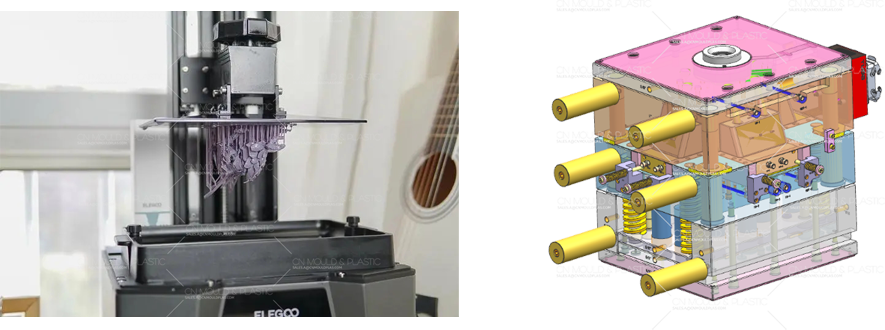

The manufacturing and forming methods of the two are different. 3D printing is also called rapid prototyping. 3D printing technology is the use of powder metal or plastic and other bonded materials to print layer by layer to construct the object technology. And it is achieved using digital technology material printers. It builds up bit by bit and finally prints the finished product.The mold manufacturing is the use of 3D modeling software to draw mold drawings, after continuous adjustment to achieve the molding effect.

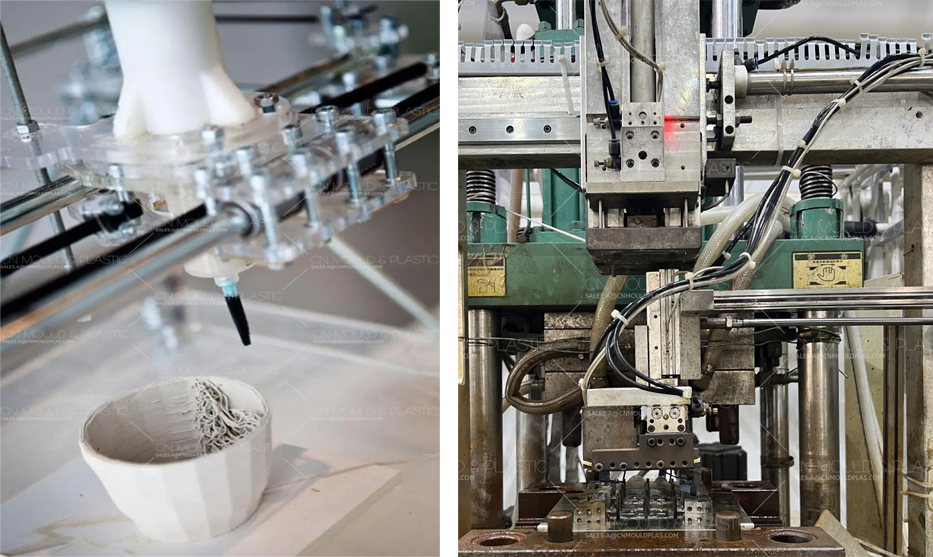

The uses of the two are different. 3D printing is mainly used for small complex parts, while traditional molds are mainly for injection molding, die casting, rubber and stamping products.

The strength and accuracy of the two are different, and the strength and accuracy of 3D printing involve many factors, the accuracy of the 3D printer, the quality of the selected material and the accuracy of the 3D model diagram all determine the accuracy of the product. The strength and accuracy of the mold mainly depend on the actual needs of users.

For the materials required for 3D printing, the most suitable printing materials can be selected according to the needs of users. Although the traditional mold is very durable and affordable, most of them are made of steel, and some are even made of cemented carbide.

3D printing molding time is long, relatively low economic efficiency for mass production, more suitable for single pieces and small batches. 3D printing focuses on small batch customization, high precision and high-end product manufacturing. The production time of steel mold is relatively fast, and the economic benefits are relatively high for mass production.

In general, due to the technological development of the mold has become increasingly mature, whether from the perspective of practicality, efficiency, and cost, it is ahead of 3D printing, but 3D printing with its strong printing ability, is also the most considerable production force in the future.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk