In the quality inspection, there are several cases of deformation, which need specific analysis. Deformation is divided into several cases of overloading deformation before packaging, deformation after packaging and deformation after the ejection of plastic parts.

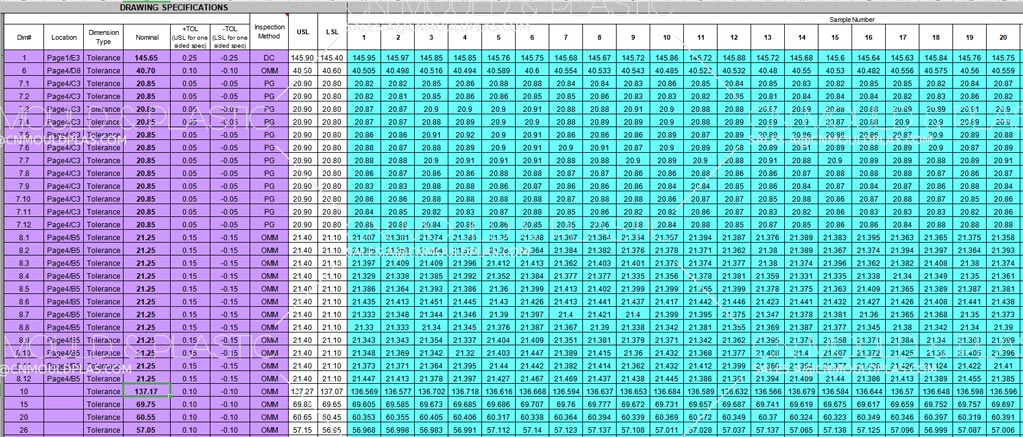

When QE saw the deformation, many people directly said that the deformation caused by improper packaging in the process of cause analysis. However, it may be caused by incorrect mold dimension which is too close to upper / lower limit, or the shrinkage rate is not well considered during design stage. For example, when a complaint of deformation is received. Firstly, our QE had traced down the specific packing list and found out the specific production lot number. After reviewing the OQC reports and IPQC report, there is no deformation reported. By reviewing IPQC first sample of the specific production lot and deformation shape of the part, our QE ruled out the possibility of negligence of QC.

Therefore, the QE had shift his focus to the whole transport process. The whole shipping quantity is around 10 cartons. Therefore, it's unlikely to have overloading issue inside our factory because each stack is around 7 cartons but it's possible during the whole transport. This product is transferred to a factory 300km away from ours, using trunk, and we have no idea how the cartons were stacked.

The most obvious manifestation of the shrinkage of injection molded products is that the size has become smaller. At this time, it is necessary to measure through the measuring tool, if the measurement value is significantly less than the standard value required by the drawing, it indicates that the product has shrunk. Second, the appearance of the judgment. In addition to the size, the shrinkage of injection molded products will also affect the appearance to varying degrees. When we see shrinkage marks, it may be due to two reasons :1. The wall thickness is too thick; 2. The parameters are not correct when injection molding, generally adding holding pressure can compensate for some shrinkage.

The shrinkage of plastic parts refers to the phenomenon of depression on the surface of the product, which is actually unacceptable. However, we make a comprehensive judgment in the following cases:

1) Molding. Improper molding parameter setting will also result in product shrinkage.

2) lmproper part design. In the product mold design, if the thick wall is too thick, it will also cause shrinkage.