There are three main indicators to measure the success of a business, that is, the increase in employees, turnover and profits; There are also three main indicators to measure the success of an enterprise's manufacturing management, namely manufacturing cycle, resource efficiency and process stability. Key Performance Indicator (KPI) can help you evaluate productivity, quality, customer satisfaction, and profit, and you can use different KPI to analyze improvement operations throughout your production line. Here are some commonly used KPI:

1) On-Time Delivery to Commit - This metric is the percentage of finished products that manufacturers deliver to customers as promised.

2) Manufacturing Cycle Time - Measures the time from order acquisition to production to finished product production.

3) Time to Make Changeovers - Measures the speed or time it takes to change a production line from producing one product to producing a different one.

1) First Pass Yield - represents the percentage of products that are correctly manufactured and meet specifications for the first time in the manufacturing process, without scrap or rework.

2) Customer Rejects/Return Material Authorizations /Returns - Measures the number of times a customer rejects a product or requests a return based on a bad or substandard product received.

3) Supplier's Quality Incoming -- Measures the percentage of quality materials entering the manufacturing process from a designated supplier.

1) Throughput - Measure the number of products produced by machines, production lines, equipment in a given period of time.

2) Capacity Utilization - Indicates the proportion of capacity utilization at a given point in time.

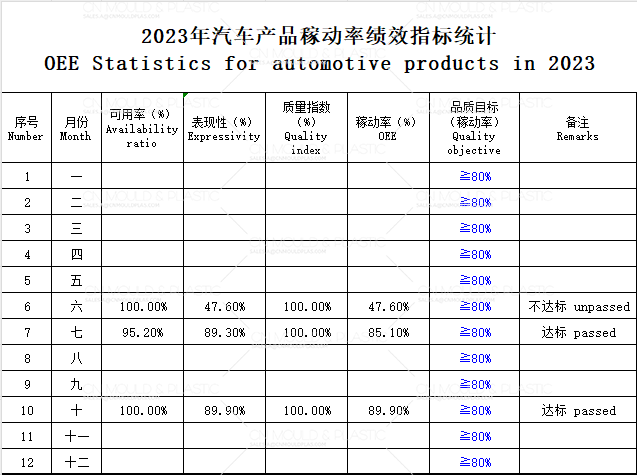

3) Overall equipment efficiency (OEE) - OEE can be used to indicate the overall effectiveness of the production equipment or the entire production line.

4) Schedule or Production Attainment - The percentage of time to reach the target production level within the specified time.

WIP Inventory/Turns - A common ratio calculation used to measure the effective use of inventory. It is calculated by dividing the cost of sales by the average inventory used to produce those goods.