The working principle of 3 Shot Injection Molding refers to that in an injection molding machine, multiple injection devices, and multiple color supply systems are set up in the mold, and plastic materials of different colors are injected into the mold at the same time, so that the molded plastic products have a variety of colors.

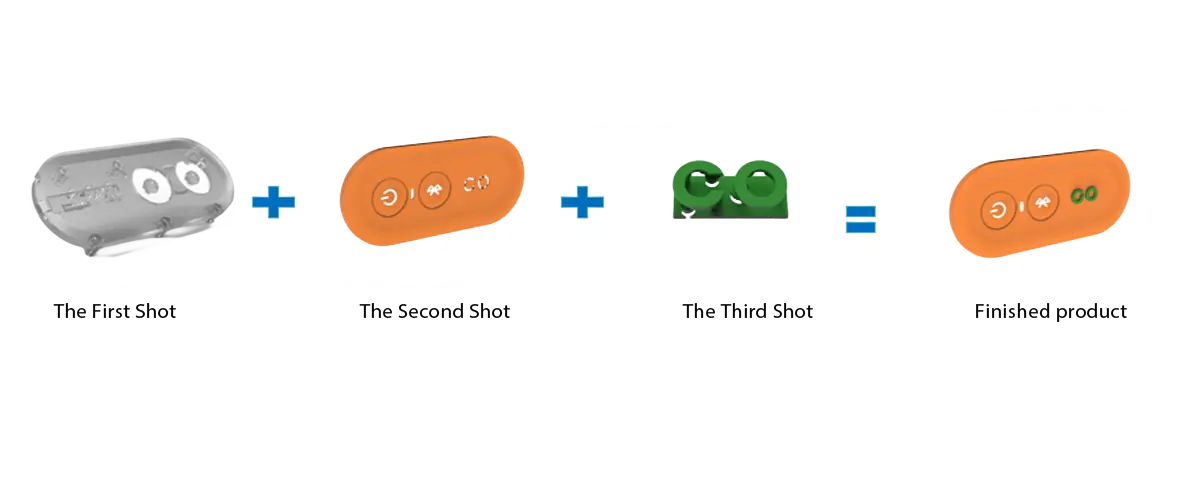

This process consists of three stages, called the First Shot, the Second Shot, and the Third Shot.

In general, there are two types of Three Shot Molding machines, one is a Two-station machine(commonly known as false Three Shot Molding machine), and the other is a Three-station machine (commonly known as true Three Shot Molding machine). In fact, the difference between the two is not "true or false", but according to the product structure design (two pairs of molds or three pairs of molds) to use different turntable control methods.

The Two-station is that the turntable rotates in two positions, which is equivalent to the 180-degree turntable control mode of the Two Shot Molding machine. When the boundaries of two components in the product are not adjacent (can be designed in the same pair of mold) and only two pairs of molds are needed to produce three components of the product, the Two-station machine is suitable.

The Three-station is different. The turntable can be positioned in three positions. When the boundaries of the three components in the product are adjacent and three pairs of molds are needed to produce three components of the product, the Three-station machine is suitable.

Let's take the example of a side keyboard made of 3K Molding. Consumer electronics are constantly working to become more compact and integrated, including being small, sophisticated, waterproof, and dustproof. CN Mould & Plastic Limited has rich experience in the production of Three Shot products. The steps for manufacturing the side keypad are listed below:

1. The First Shot: Injects white PC(Polycarbonate) to form the base.

2. The Second Shot: Injects blue Thermoplastic Elastomer(TPE) to cover the soft shell on the base.

3. The Third Shot: Injects Thermoplastic Elastomer(TPE) to form the Purple letter LOGO.

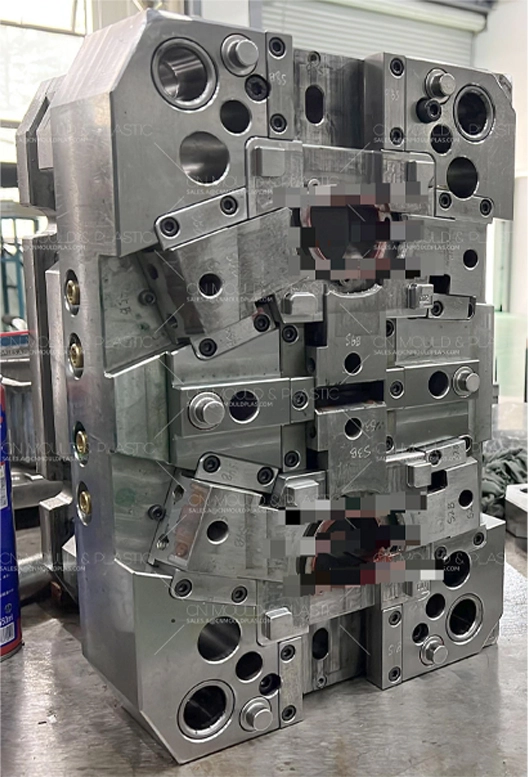

Three Shot Molding technology is a comprehensive technology that combines multi-material injection molding, vertical rotary injection molding machine, automatic extraction and implantation, etc. The advantages of Three Shot Molding lie in achieving integrated molding, multi-color molding, eliminating assembly, and realizing multi-functional integration.

The key of this technology lies in the flexible application of vertical injection molding machine. Multi-station cooling can reduce molding time and increase production, while making it easier to extract products and automate production. It overcomes the disadvantages of the traditional horizontal injection molding process and is the preferred technology for the production of consumer electronic product shells.