Both insert molding and Overmolding can produce products made of multiple materials without needing adhesive, which eliminates the need for additional assembly and enhances the final product's characteristics.

Even though insert molding and Overmolding may seem alike, there are noteworthy differences between the two techniques.

The key difference is that insert molding is a one shot injection molding method that uses pre-prepared inserts, whereas Overmolding is a two-shot injection molding process that injects one plastic to cover the substrate plastic.

1. Reduce the cost of assembly and labor costs by eliminating of necessary assembly operations such as gluing and fastening.

2. Reduce the size and weight of the part. By combining plastics with stamping parts, insert molding makes smaller and lighter parts.

3. Enhance design flexibility and create design functions and features that plastic alone cannot achieve.

4. Increase the strength and durability of parts.

5. Improve the consistency of parts.

1. Purchase order received; assess feasibility.

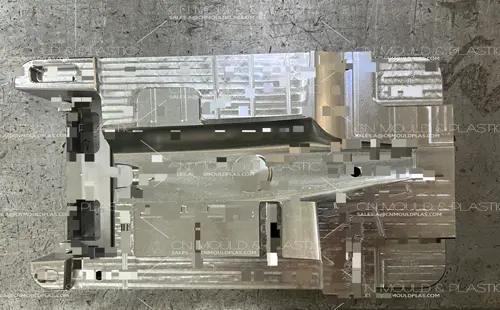

2. DFM approved mold design, and prepare stamped part.

3. Design approval and mold build start.

4. Manual stamped part placement and machine process.

5. Part finished and FAL & Sample Sent.

6. Sample approval and mass production.