The Runner System refers to a channel in the mold from the nozzle to the entrance of the cavity. It can be divided into two types: ordinary runner system and hot runner system. Its role is to smoothly introduce the molten plastic into the cavity, and transfer the pressure to various parts of the cavity to obtain plastic parts with clear appearance, smooth surface, and stable size.

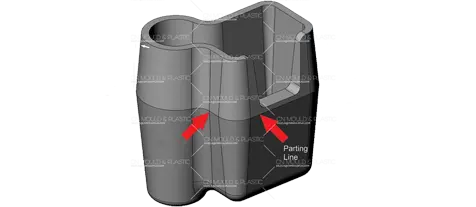

The design of Runner System directly decides the efficiency and quality of injection products. The structure of the Runner System consists of two parts: runner and gate. The runner design is as short as possible to ensure the minimum resistance value. The type and location of the gate directly affects the quality of the plastic product.

The Runner System consists of four parts:

Sprue

Sprue is a flow channel from the nozzle of injection machine to the runner. Sprue is the first flow channel through which the molten plastic passes, so its size directly affects the flow speed and mold filling time of the melt.

Runner

The runner is a flow path between the sprue and gate. It is a transitional channel through which the melt flows into the cavity from the sprue.

Gate

The gate is the narrowest part of the plastic flow into the cavity, and it is also the shortest part of the Runner System.

Cold well

Cold well are generally set at the end of the sprue or runner to store cold material so that the melt can be successfully filled with the cavity.

1. Select the appropriate gate types, number and location

According to the process characteristics of plastics, reasonably design the Runner System, correctly select the type, number and position of the gate, so that the melt can quickly and evenly fill the cavity under the same pressure and temperature.

2. Good venting

The Runner System should be able to successfully guide the melt to fill the cavity, so that the gas in the cavity can be smoothly discharged.

3. Avoid flow of plastic melt directly impacting core and insert

The purpose of this is to prevent the core from bending or breaking and to prevent the deformation of the insert.

4. Reduce the clamping force

The projected area of the Runner System on the parting surface should be as small as possible to reduce the clamping force.

According to the shape, size and location of the gate, the classification of the types of the gate is wide, but the common gate types are roughly divided into the following:

1. Sprue gate

Feature: Suitable for single cavity mold. The pressure loss is small and the feed speed is fast.

Shortcoming: It is difficult to remove the gate and marks are obvious.

2. Pin gate

Features: Suitable for plastic flowing fast, easy to remove the gate and does not affect the appearance of plastic parts.

Shortcoming: Not suitable for thin plastic parts because it’s easy to crack.

3. Side gate

Feature: Easy processing, flexible choice of gate location, easy to take out.

Shortcoming: Plastic parts are easy to cause weld marks, shrinkage holes, depressions and other defects.

4. Sub gate

Feature: The feed point in the hidden place does not affect the appearance of the plastic part.

Shortcoming: Sub gate is not suitable for some products that need to keep the gate on the mold surface.

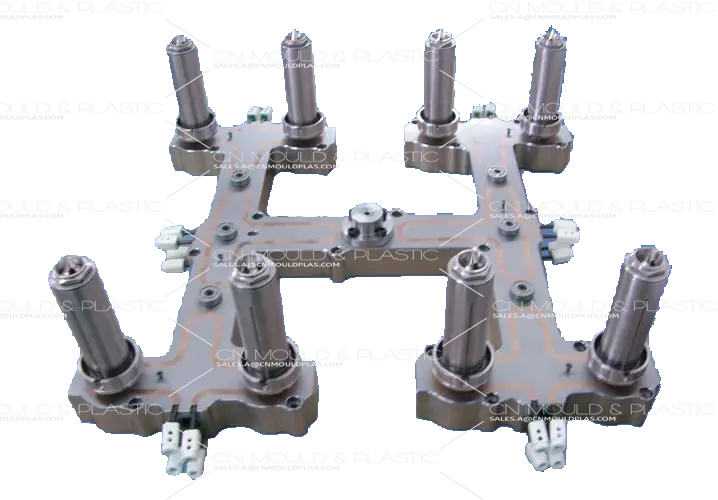

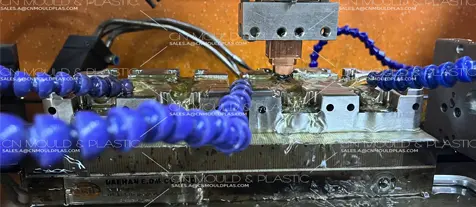

Hot runner technology is an advanced technology applied to plastic injection, and is a hot direction in the development of plastic injection molding technology. The hot runner molding means that the injection mold is set up a heater so that the molten material sent to the gate by the nozzle is always in a molten state, and there is no need to remove the waste material during each mold opening, and the molten material remaining in the Runner System can be injected into the cavity during the next injection.

Advantages :

1. Save raw materials and ensure high quality products.

2. Shorten the molding cycle, improve the efficiency of the injection machine.

3. A single product can be formed directly by the side gate, reducing the subsequent processing of the product.

4. Reduce injection pressure and clamping force.