We can harden practically any material (rubber, plastic, etc.) to a spotless cavity shape at CN Mould & Plastic Limited. This simplifies your production process while providing you with a competitive advantage because:

High appearance accuracy: Rubber compression molding is a kind of hydroforming process, because the rubber is always close to the part during the forming process, so the surface of the part has no scratches. In addition, under high pressure and friction, the surface quality of the parts is good, and the shape accuracy is high. At the same time, due to the uniform thickness change, the damage rate inside the material is greatly reduced.

Short production cycle, low manufacturing costs: Because there is only one rigid mold, this greatly simplifies the mold, so that the press preparation time is very little. Even if we need to test the mold, its time is reduced by more than 50%.

High production efficiency: Because several molds of different products can be placed on the workbench at the same time, several products can be produced at the same time in one cycle.

More complex shapes can be made: Rubber compression molding is suitable for molding poor performance or high strength materials such as aluminum alloy, magnesium alloy, titanium alloy, stainless steel. It can also mold composite materials, which is very helpful to reduce the weight of parts.

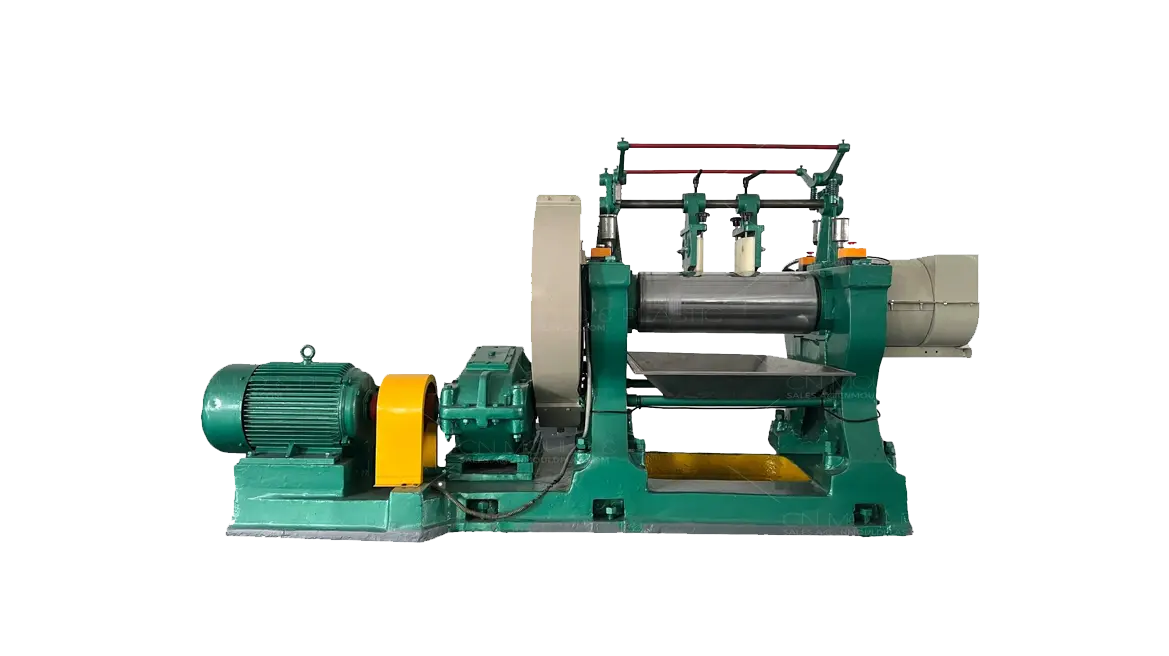

Place small pieces of rubber in the mold.

After heating the mold to 180°, the upper and lower two molds are combined, and the gummy rubber pieces are formed close to the inner wall of the mold under high temperature and pressure, and the molding is completed after 10 minutes.

Demoulding, transfer to grinding and trimming process.

Compression molding is a rapid processing process in which rubber is compressed in a preheated die cavity.

1. Simplify the mold, save production time, improve efficiency

2. The cost is low and the flexibility of the shape of the parts can be produced. Besides, the surface quality of the parts is high.

Both require supporting molds (compression molding molds are cheaper), and the molding process is carried out under high pressure heating. The difference is that injection molding is mainly made of thermoplastics, and compression molding is mainly made of thermosetting plastics.

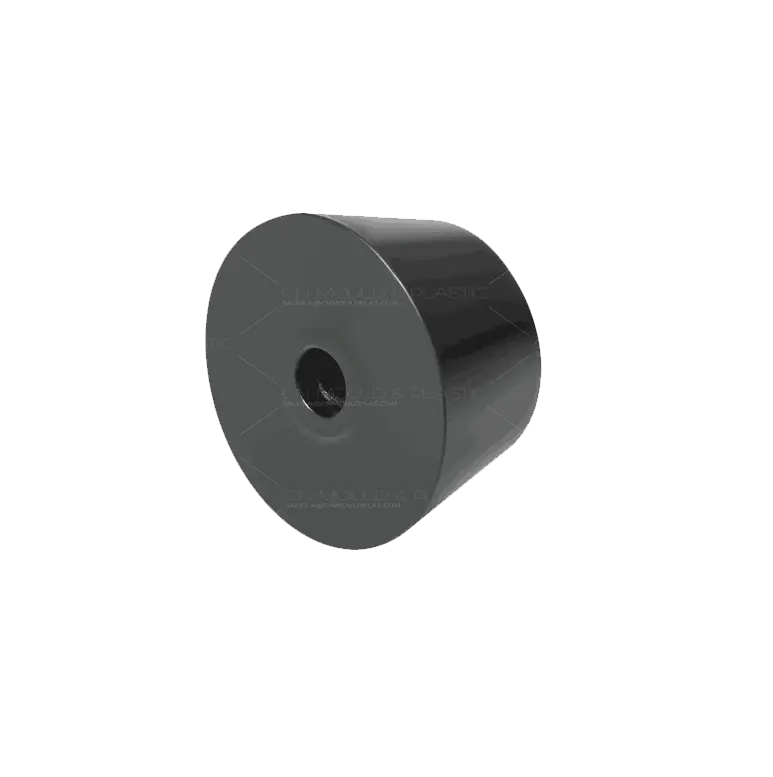

Electronic product shell, rubber keys, keyboard film, rubber washer and other anti-corrosion product parts.