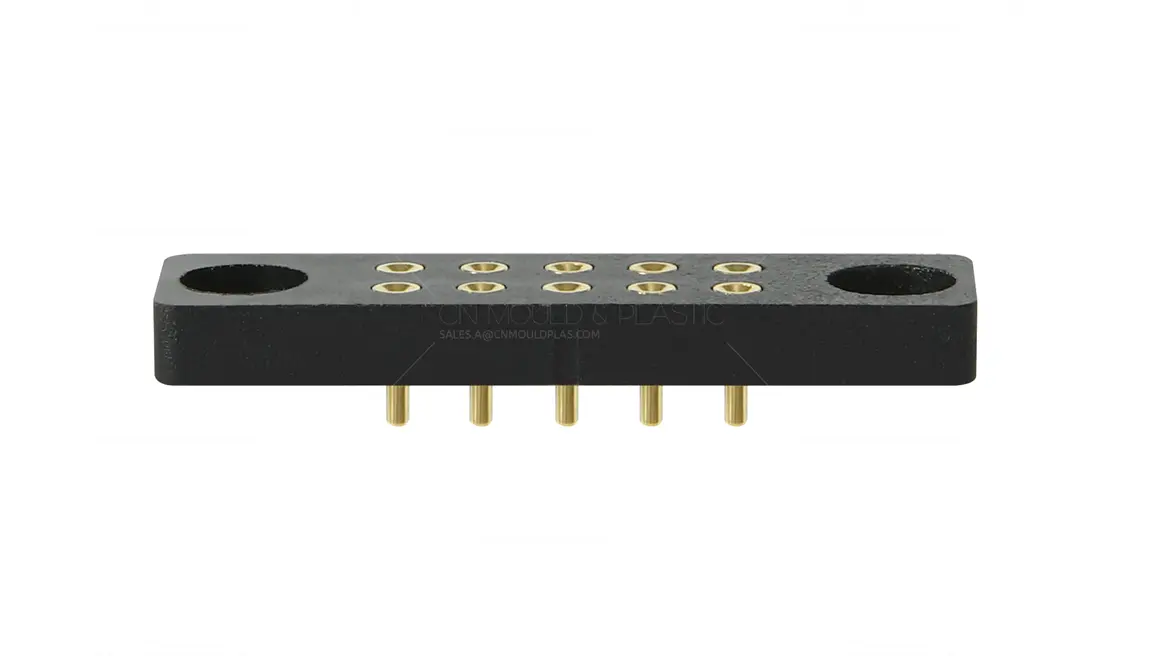

1. The pogo pin insert molding is required to withstand high pressure and high temperature during the injection molding process without affecting its current.

2. Since insert molding still relies on plastic to maintain the position of the pogo pins, it is important to design the mold to precisely fix the pogo pin.

3. When the part is still inside the closed mold, the shrinkage of plastic begins immediately after the injection molding is completed. Moreover, when the mold is closed, the pogo pins will limit plastic shrinkage.

Therefore, the size and shape of the pogo pins, the shrinkage rate of the plastic, and the engineer's experience must all be taken into account.