We need to consider two important process issues - overmolding area and shrinkage rate - when dealing with the two plastic injection overmolding materials. To ensure proper bonding between the two distinct hard plastic materials, the following criteria must be fulfilled:

STEP 1: The substrate material is injected into the mold cavity.

STEP 2: After the substrate cools and solidifies, the overmolding plastic is injected around the substrate.

STEP 3: The overmolding plastic cures and fully covers the substrate.

STEP 4: A final overmolded plastic injection product is removed from the mold and post-process.

Due to the wide selection of materials for plastic overmolding process, it can be used in almost any project you can need. From rubber grips to waterproof seals, plastic overmolding is a cost-effective and highly productive process that can produce various reliable quality products.

At CN, our team can assist you in producing the plastic products you want through this technique, such as, but not limited to:

1. Consumer goods

2. Automotive part

3. Electronic devices and enclosures

4. Medical tools and devices

Products that are manufactured using Plastic Overmolding offer a range of benefits for both manufacturers and consumers, when compared to other alternatives. These benefits include:

1. Improve component dependability.

2. Enhance the stability and strength.

3. Lower labor and assembly expenses.

4. Reduce the weight and size of the product.

5. Increase the flexibility of the design.

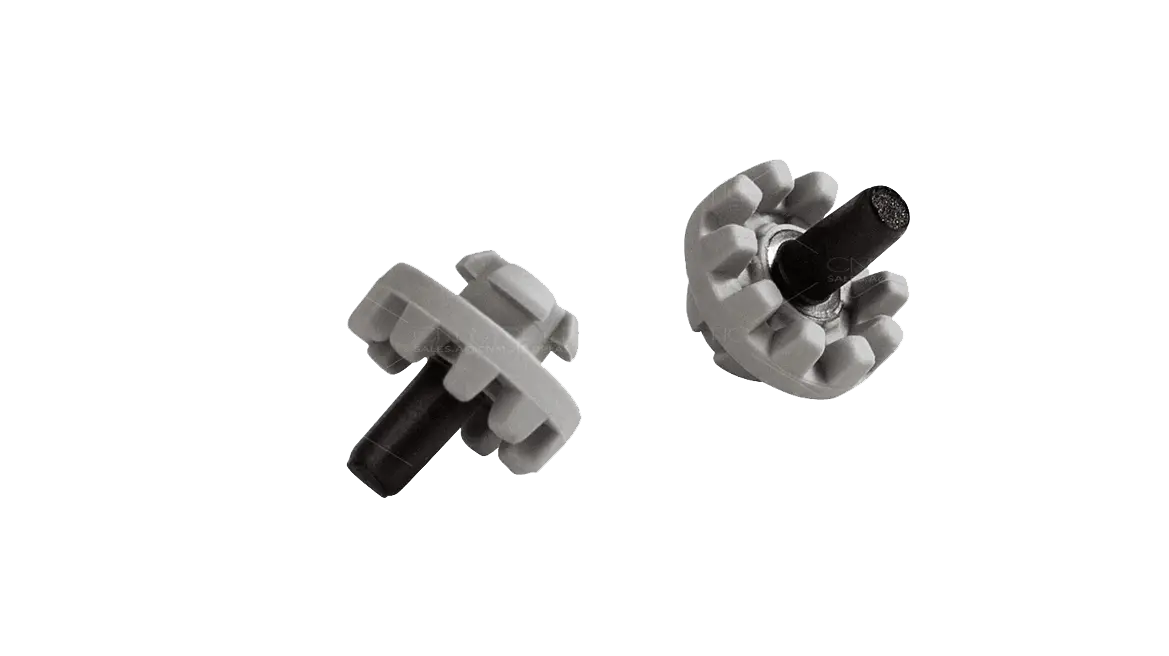

Plastic Overmolding is entails molding one hard plastic material onto another hard plastic material.

While plastic overmolding involves molding plastic over an existing object, insert molding involves placing a pre-formed insert (such as a metal component) into the mold cavity and then molding plastic around it.

Temperatures, molding area and shrinkage rate.