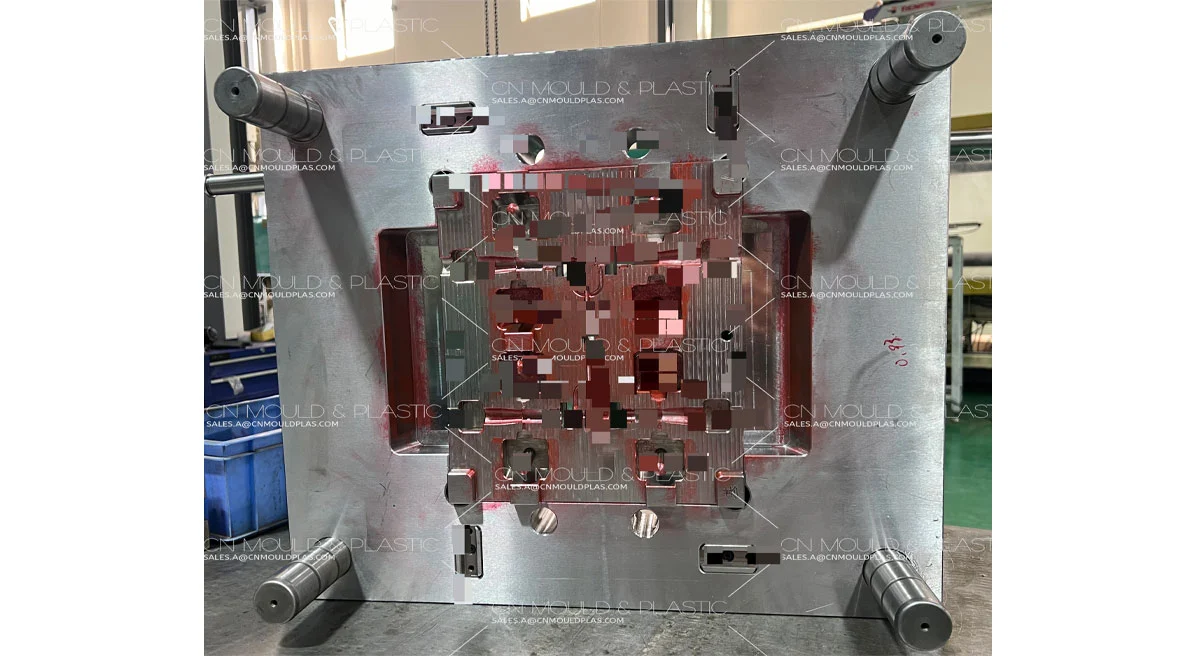

Challenges we overcome during the PCB Injection Molding process

For some cables, the PCB is often fastened in the shell by injection molding to achieve certain waterproof, ash, and dust proof purposes. One of the disadvantages of injection molding is that the injection temperature is high, which may damage the parts on the PCB; The second disadvantage is that the PCB needs to be placed into the mold first, which will increase the injection molding cycle. However, we have overcome the above technical difficulties, and strictly control the injection Molding temperature in PCB Injection Molding to ensure that PCB is not damaged.