As a constantly evolving technology, Multi-Component Molding is currently being used in a number of innovative and ground-breaking ways. Some of the newest Multi-Component Molding technologies include:

In order to ensure that the components meet the essential requirements and performance standards, they are continuously inspected and tested as part of the quality control procedure for Multi-Component Molding. Try the following techniques for Multi-Component Molding quality control:

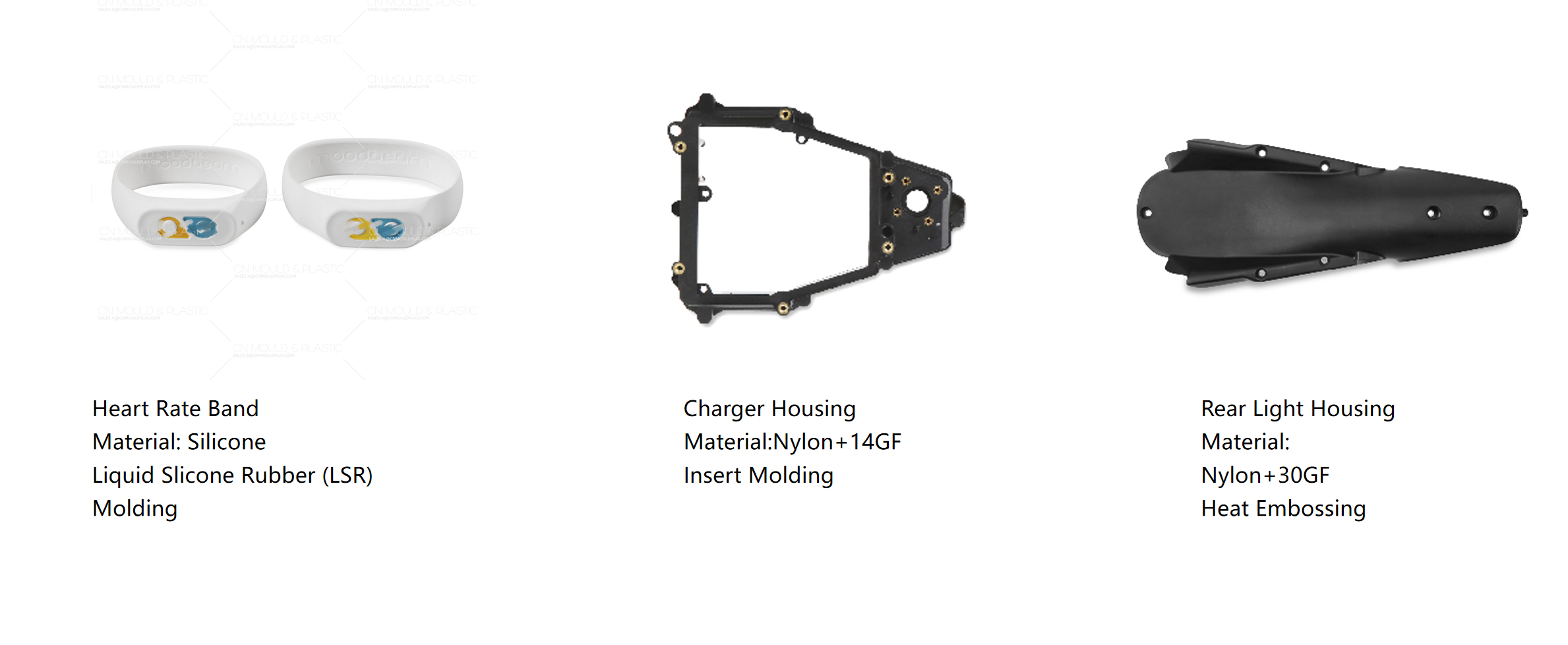

Multi-Component Molding, a flexible manufacturing method, may be used to create a range of complex plastic items with multiple colors or characteristics in a single cycle. A few examples of items that are regularly made utilizing multi-component molding are shown below:

Multi-Component Molding permits the fabrication of parts with different degrees of hardness or softness in different parts of the part.

Thermoplastics such as PP, PC, and ABS, Thermoplastic elastomers like TPEs, TPU and TPV, silicone, metals and other additional materials.

Material testing, mold design and verification, dimensional inspection and industrial parts.

Automotive components, consumer products, medical equipment, sporting products and industrial parts.