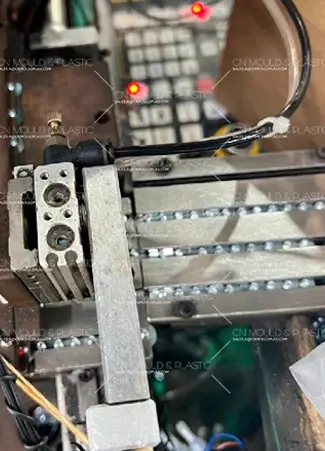

Equipments in CN Mould & Plastic Limited develops for a variety of assembling products. Depending on requirements, several production processes are combined and integrated into our systems. For instance:

Connecting

Dosing

Feeding

Screwing

Separating

Sorting

Adhering and distributing

Greasing and oiling

Drill, harden, and laser cut

Inserting and positioning

Transforming

Soldering and welding

Weighing

Marking and identifying

CN Mould & Plastic Limited is able to assist with challenging Assembly Automation assignments. We use our equipment and technology to assemble a wide range of items for different industries. We offer specialized automation solutions that are the most cost-effective, secure, dependable, and profitable in the market.

The automated assembly equipment is planned, designed, and built in CN Mould & Plastic Limited. Once finished and delivered, they can be put into use right away at the customer's location. The widest variety of technology, components, materials, and procedures are used for the realization. Depending on the special requirements and the environment's economic and technological support, the equipment and systems are either totally or partially automated. Our technicians, sales representatives, development engineers, designers, electricians, programmers and tool makers offer the best results that frequently exceed the client's expectations.

CN Mould & Plastic Limited carefully monitors and ensures the quality of the entire development process. We create innovative, eco-friendly solutions for the automation market in this way. Ready for Industry 4.0, our revolutionary machinery and systems, is founded on a foundation of continuous innovation, forward-thinking, interdisciplinary collaboration, as well as adaptive and lean structures. Our internal assembly procedures are of great quality owing to working in this highly controlled, hygienic environment, leading to in the best finished goods for our customers.

Robotics-assisted Manufacturing System

In CN Mould & Plastic Limited, lean manufacturing practices and automation are routinely employed to increase production safety, ensure product quality, and minimize costs. Robot assistance was used almost everywhere in its manufacturing facility, including the intricate de-molding of LSR and thermoplastic elastomer parts and the speedy transfer of injection-molded plastic parts to printing systems.

Automated Module Assembly System

CN Mould & Plastic Limited has a history of internally developing its automated module assembly technology, particularly for producing electronics and automotive components requiring complex sub-assemblies.

In-Mold Assembly

High levels of automation are utilized during the assembly process inside the mold, which decreases production costs and lowers the risk of human mistake while reliably producing high-quality semi-assembled or finished products. It has numerous uses in the automotive, electrical, and medical industries.