The number of cavities not only affect the manufacturing cost of the mold, but also affect the cost of the injection molding product, so it is very important to decide the number of cavities in mold design. Here are the factors to consider when determining the number of cavities:

The determination of the standard mold size should consider the structural form of the mold and the feasibility of the manufacturing process. In general, after the concept is confirmed, the size of the mold base is determined.

First determine the number of cavity, parting surface position and gate type, then determine the arrangement of plastic parts in the mold. Note that the arrangement of plastic parts in the mold will directly affect the size of the mold base.

Determine the structure of the cavity and core, that is, according to the structural characteristics of the mold to determine the use of Cut-in-the-solids or Laminated Constructions, and determine the overall size or the approximate size of the cavity insert.

Determine the structure and position arrangement of the slide mechanism, guide mechanism and ejector mechanism.

Adopt standard mold base. According to the structural form and thickness requirements, find similar mold size in the standard mold base.

The selection of screws should pay attention to the following problems:

Screws mainly bear tensile stress, and their size and quantity are generally determined according to the die thickness and other design experience. Small and medium-sized molds generally use M6, M8, M10 or M12 screws, large molds can choose M12, M16 or larger specifications of screws. Then determine the screw specifications according to the die thickness. Screw specifications can refer to the figure below:

Screw specification selection | |||||

Die thickness H/mm | <13 | 13-19 | 19-25 | 25-32 | >32 |

Screw specification | M4.M5 | M5.M6 | M6.M8 | M8.M10 | M10.M12 |

The screws should be arranged near the outline of the fixed part as far as possible. When the fixed part is round, 3 to 4 screws are generally used, and when it is rectangular, 4 to 6 screws are generally used.

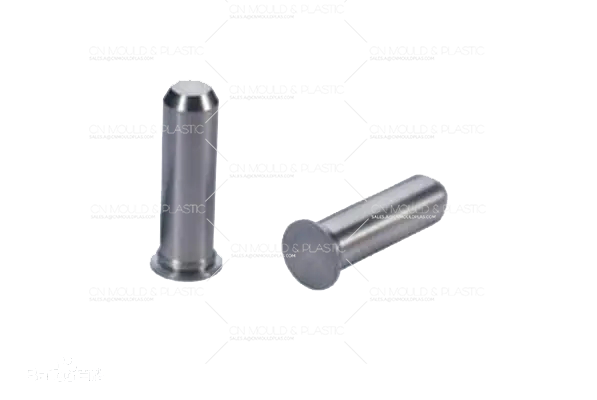

Dowel pins are usually made of high hardness alloy steel. It has the characteristics of precise size, smooth surface and high hardness, and is an important part for connecting and positioning machine parts.

Dowel pin selection principle:

1. Dowel pins are divided into cylindrical pins and conical pins. The cylindrical pin should not be disassembled frequently in order to ensure the positioning precision and the fastness of the connection. The conical pin is easy to install, and the influence of multiple installation and disassembly on the positioning accuracy is small.

2. The two dowel pins should be placed near the outline of the fixed part as far as possible and staggered.

3. The diameter of the dowel pin should be selected according to the displacement force and the size of the mold plate.