Marine Electrical

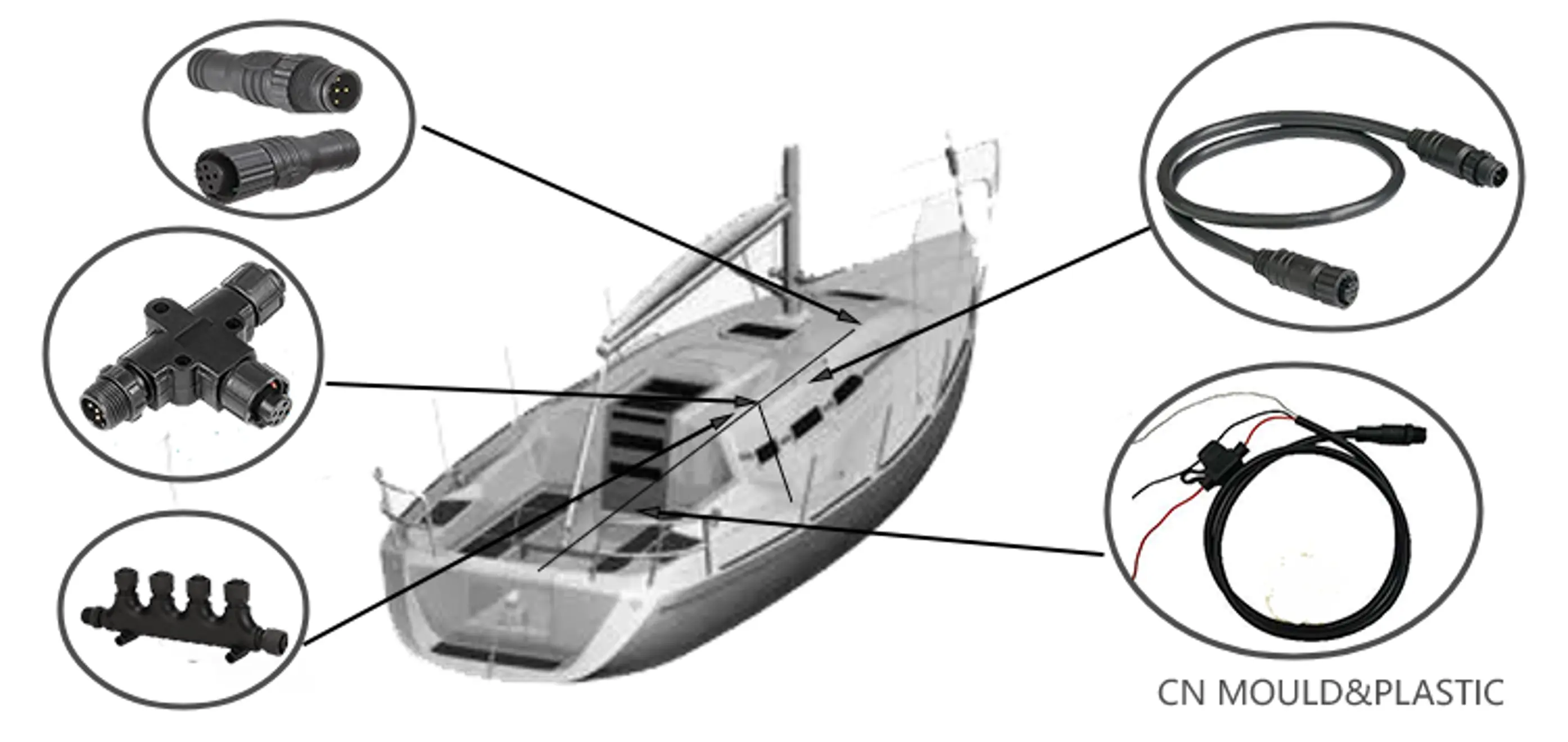

Marine Electrical is subject to the NMEA 2000, which is the maritime industry standard for the way electronics and marine instruments communicate with each other.

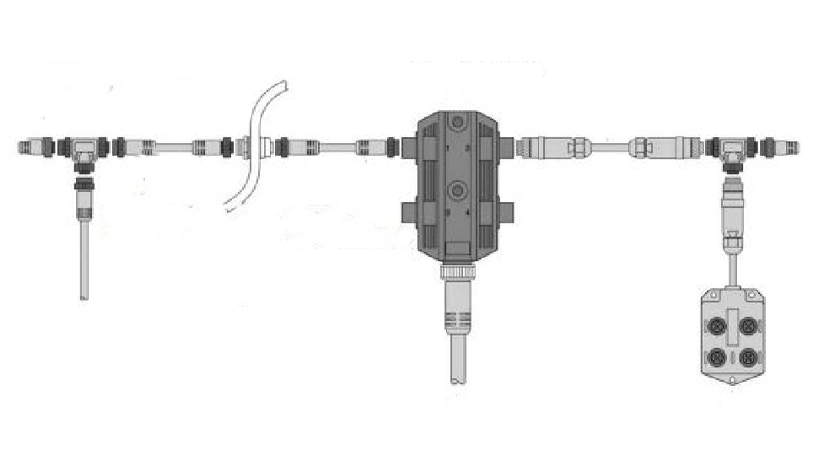

How does NMEA 2000 work? It is a multi-speaker system, which means it can send and receive signals at the same time.

This ability to process large amounts of data enables a single backbone system to connect multiple devices from many different manufacturers.

The NMEA 2000 backbone can connect devices(Engine data/Outboard Motor/Fusion Radio/ GPS/Radar/ Chartplotter/Transducer). There are several benefits to using NMEA2000 equipments for Marine Electrical systems. They include easy installation, lower installation costs, and the ability to mix products from different manufacturers to build your perfect Marine Electrical system.