Silicone also has a wide range of application fields and unique qualities. The following is a list of the characteristics of LSR + thermoplastic:

Products made of LSR + thermoplastic come in a variety. Pressure molding and injection molding are the two primary forms of silicone rubber product manufacture that can be distinguished by variances in equipment and processes.

Pressure molding involves placing the rubber material or semi-finished goods straight into the mold cavity and applying pressure to the machine to cause heating and vulcanization. Here is how it works:

Rubber Material → Shear weighing or other preforming → Loading into the mold cavity → Pressure and vulcanization → Starting to take parts → Repair flying-edge → Finished product quality inspection.

Direct rubber material injection into the mold cavity using an injection machine, followed by vulcanization, produces the process' end products. The following is the production process:

Plastic preheating plasticization → Injection into the mold → Vulcanization → Opening the mold to take parts → Repair the flying edge → Finished product quality inspection.

Dust proof

Production technology for LSR + thermoplastic molding provides excellent protection. It has an efficient surface oxidation treatment for dust resistance.

Soft and durable

The use of silicone makes the product have excellent tear resistance at high temperatures, and feel very soft and durable.

Precision liquid silicone overmolding

A technology called LSR + Thermoplastic Molding can effectively waterproof, dustproof, hockey, and stain with dust. Excellent tear elasticity and abrasion resistance performance.

Waterproof and anti fall

Silicone that is FDA food-grade and non-toxic environmental protection. The silicone belt is colliding with the machine body and undergoes integrated molding production and processing, allowing it to have a waterproof and anti-fall effect. applications for smart wearables are numerous.

Rich Experience

With satisfied customers all over the world, CN Mould & Plastic Limited has more than 17 years of expertise in LSR + Thermoplastic. Our specialists will work closely with you to fully grasp your needs and propose practical solutions for your project. We can assist you throughout the entire process and deliver LSR + Thermoplastic materials at affordable costs.

Premium Quality

Our certifications for ISO9001:2015, IATF 16949:2016, and ROHS ensure the high standard of our overmolded goods. Additionally, we follow a thorough quality control procedure to guarantee that every product we supply to our clients is of the highest caliber.

High Efficiency

Modern, high-performance equipment is used by CN Mould & Plastic Limited, and we continuously improve our internal production procedures so that we can provide overmolding services with the highest level of effectiveness.

Polyethylene (PE), Polycarbonate (PC), PEEK, Nylon (PA 6, PA66, PA 12).

When designing for LSR overmolding, consider the following factors:

- Material compatibility: Ensure that the LSR material and thermoplastic substrate are compatible and can achieve strong adhesion during the overmolding process.

- Thermal management: Consider the thermal properties of the thermoplastic and LSR materials, as they can affect the cure time and shrinkage during the molding process.

- Part design and gating: Optimize the part design to allow for easy flow of LSR material into the mold cavity, and consider proper gating design to prevent air trapping.

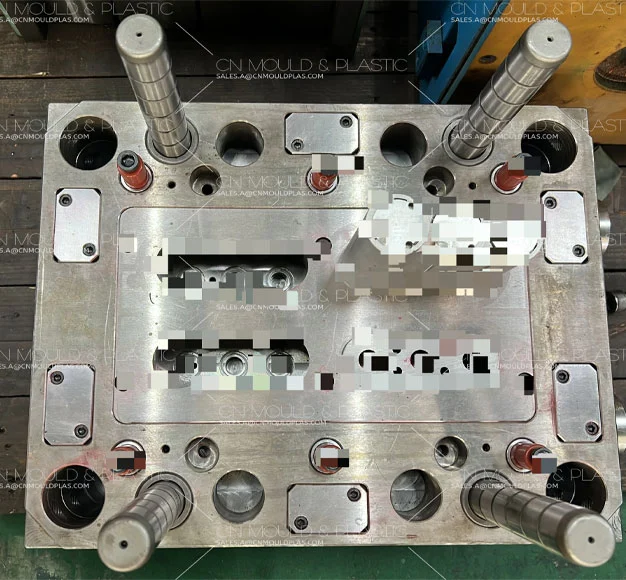

- Mold material and design: LSR overmolding typically requires molds made of materials resistant to the high temperatures of LSR processing, such as steel or alloys.

More advanced Overmolding processes are being employed increasingly frequently to produce things like baby feeding bottles, medical devices, and sealing rings for phones.