1. The prototype approach assists users and programmers better understand the need for products and services.

2. The prototype approach provides an effective teaching tool.

3. The performance of the product, the application of the primary goods and services, the viability of the product design, and the evaluation of the product's final outcome can all be easily assessed when using the prototype method.

4. The final iteration of a software prototype can be valuable in developing the system's final product, some of which can become final products and some of which can be slightly modified to become a component of the final product.

We have seen countless digital and 3D prototypes throughout the years. Important decisions are frequently made at an early stage of the prototype design process. These are typically designed with the end user in mind rather than the part producer. This is incorrect.

Creating Efficient Prototypes

It goes without saying that your product's end user must be satisfied with it, but it is advisable to seek professional advice on the design of your prototype before committing to a wasteful, ineffective, or problematic element.

Vendor Involvement

Here's where we step in. It is extremely recommended to involve vendors in the process early on. Before you even begin manufacturing, your vendor is aware of the propensities of plastics, molds, and machinery to save time, cost, and waste. As you create a prototype design, we can review it and offer support. This can save both parties money, time, and headaches during the production process.

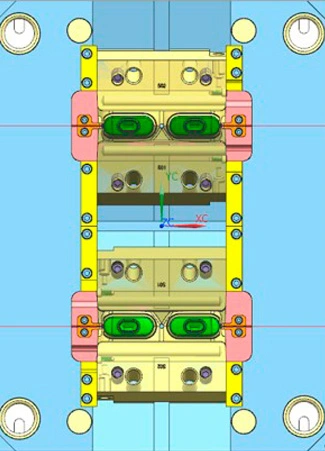

SolidWorks CAD

To review part designs, we utilize SolidWorks CAD software. We can more properly estimate your project and identify potential issue areas before molds are manufactured by using one uniform system for review. The cost of designing and creating a mold is high. Modifying the part design after the construction mold has been finished and the validation process has begun is quite expensive. This is why having a seasoned eye assess part designs before the prototype and mold are finished is invaluable.

In order to create and market new plastic parts, CN Mould & Plastic Limited works with clients using its highly specialized and narrowly focused Prototyping expertise. Collaboration and knowledge exchange to support the prototype process:

Make test pieces and prototype molds to serve as the framework for future production molding.

Set up the project's profile for the prototype's targeted learnings.

Develop alternative part designs to verify a part's aesthetics and functionality.

Analyze the technical and commercial benefits of potential production molding methods.

Create a plastic product design. Ensure that the concept is workable and take feasibility and manufacturability into account while designing a plastic product.

Product engineering with Moldflow. Evaluate the wall thickness of the gate to allow the plastic material to flow through it completely without overflowing.

3D printing/Machining.

At CN Mould & Plastic Limited, materials are appropriately selected for rapid prototyping.

1. 3D printing Prototype: We use SLA technology to quickly produce complex prototypes. The suitable materials include PP, PA, ABS.

2. CNC Prototype: Aluminum alloy, bakelite, stainless steel, ABS, PC, PMMA, PP, PA66, etc.

3. Silicone Prototype: ABS, PC, PP, PU, etc.