CN Mould & Plastic Limited has a plant of 10,000 square meters for mold manufacturing and injection molding in Shenzhen and Zhongshan, Guangdong, China. Being an injection molding experter in the industry for over 20 years and certified by IATF16949, the CN team has developed all different kinds of molds, from rapid prototypes to large-scale production molds like multi-cavity, 2K, liquid silicone rubber, inserting, and our molding press up to 1,000 tons. CN Mould & Plastic Limited utilizes state-of-the-art equipments such as wire-cut, EDMs imported from Switzerland, high-speed CNC machines, CAD/CAM, and milling, drilling, and grinding machines. Our professional group of engineers and plastic injection molding experts have over 15 years in injection molding and mold making industry on average. CN Team can always be your reliable partner to collaborate with and our friendly team is always here to help you turn your concept into a reality.

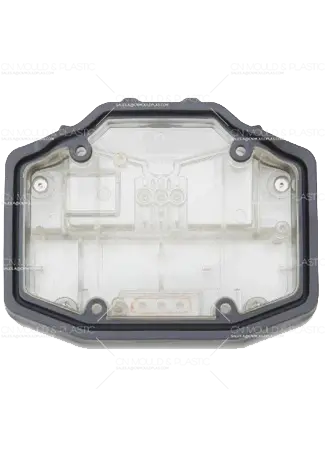

Injection molds can process a variety of plastic products, such as electronic product shells, toys, household items, auto parts, medical devices and so on. The following are some common injection mold processing products:

Electronic product shell: such as mobile phone, TV, audio and other electronic products shell, using high-strength, durable plastic material injection molding to meet the product appearance and performance requirements.

Toys: Injection molds produce a variety of toys of different shapes, including children's toys, educational toys, sports toys, etc. These toys can be injection molded with different materials, such as PE, PP, etc.

Household items: Injection molds can be used to produce a variety of household goods, such as plastic hangers, plastic buckets, plastic chairs, etc. These products have excellent durability and lightweight, which are very suitable for family use.

Automotive parts: Injection molds can be used to produce auto parts, such as doors, car dashboards, lights, etc. These products need to have high heat resistance, corrosion resistance and toughness to meet the requirements of the automotive working environment.

Medical devices: Injection molds can be used to produce a variety of medical devices, such as medical syringes, medical nonfat yarn, etc., which need to have good biocompatibility and durability to meet the strict requirements of the medical industry.

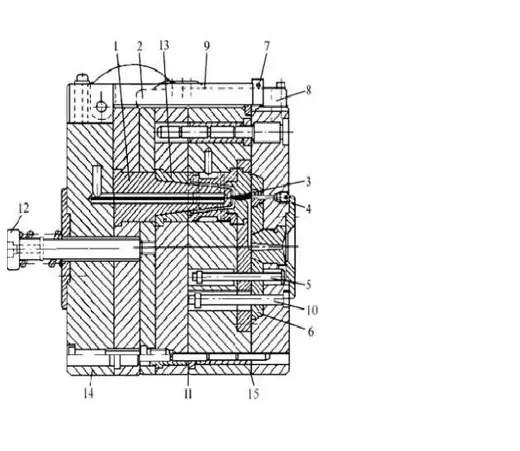

Typical Tool Structure

1. Sprue separating area

2. Latch

3. Sprue

4. Retainer pin

5. Head of bolt

6. Sprue-Stripping plate

7. Pin

8. Guide strip

9. Waterway

10. Bolt

11. Main parting line

12. Ejector pin

13. Stripper sleeve

14. Plate assembly

15. Mold cores

CNC machining is the main production procedure for tool making. Molds are usually machined out of steel and stainless steel, but sometimes aluminum is also used. Aluminum cannot withstand the tear and wear of injection molding as well as steel, but it is a cheap alternative for small-batch injection molded parts.

The core of the tool must be able to keep its precise dimensions and feature over the course of thousands or millions of injection cycles, along with all the stress and heat enforced on them. CNC machining makes forming the metals to the required tolerances simple. At CN Mould & Plastic Limited, CAD/CAM software are implemented to produce sophisticated, perfect tool for designing and machining molds.

Electrical Discharge Machining (EDM) is a machining process that utilizes electrical discharges or sparks to remove material from a workpiece. It is commonly used for machining complex shapes and hard materials that are challenging to machine using traditional methods.

The EDM process involves a workpiece and an electrode, typically made of conductive materials such as copper or graphite. The workpiece and the electrode are submerged in a dielectric liquid, which acts as an insulating medium and helps facilitate the discharge process.

When an electric voltage is applied between the electrode and the workpiece, a high-energy electrical discharge occurs in the small gap between them. This discharge creates an intense heat that melts and vaporizes a tiny portion of the workpiece material. The dielectric liquid then flushes away the molten debris, and a new discharge is initiated.

By controlling the electrical parameters such as voltage, current, and pulse duration, as well as the positioning of the electrode, precise material removal can be achieved. The process is typically computer-controlled, allowing for high accuracy and repeatability.

At CN Mould & Plastic Limited, EDM is particularly useful for machining intricate shapes, thin sections, and hardened materials, such as tool steels and exotic alloys. It is commonly employed in industries like aerospace, automotive, mold and die making, and electronics manufacturing.

CN Mould & Plastic Limited owns more than 135 injection molding machines including vertical machines and horizontal machines. In particular, we have a set of vertical injection molding machine with horizontal injection units that suits for insert molding trials. The vertical machine structure allows ease of insert placement.

Features of Injection Molding Machine

1. Vertical clamping; horizontal injection.

2. Strong structure. Clamping force is up to 500 ton.

3. The injection base height is adjustable, leading to more flexibility in mold design.

4. Diversified oil circuit system design(semi-closed, servo or high-speed injection) to meet customers' needs.

| Brand | Steel Material No. | Comparison of Standard and Properties | Hardness | Hardness after Heat Treatment | Properties and Applications | |||

| AISI | JIS | DIN | HB | HRC | HRC | |||

| ZHAOHENG | S136 | 420 Modified ESR | SUS420J2 Modified ESR | 1.2083 Modified ESR | =235 | - | HRC46~52 | High purity, fine and uniform organization, excellent polishing performance, corrosion resistance and good dimensional stability of heat treatment. It can be used for mirror molds and the production of corrosive plastics and plastics adding accelerants. |

| S136H | 420 Modified | SUS420J2 Modified | 1.2083 Modified | 30~37 | No heat hardening required | Pre-hardened die steel with hardness HRC30~37, high purity, fine and uniform organization, high-quality polishing performance, corrosion resistance, good dimensional stability of heat treatment. | ||

| H13 | H13 | SKD61 | 1.2344 | =235 | - | HRC48~52 | High toughness and good thermal fatigue performance, suitable for zinc alloy, small aluminum alloy die casting mold, plastic mold. | |

| NAK80 | P21 Modified VAR | - | - | - | 37~43 | No heat hardening required | Mirror polishing up to #8000, age hardening steel, excellent dimensional stability, excellent discharge processability and sun grain. Suitable for the production of medium mass production of simple shape, surface requirements and processing accuracy requirements of the ordinary mold such as car instrument panel, copier panel. Not suitable for the molds with Tianjin fire retardant and high corrosion requirements. | |

| P20 | P20 | 1.2311 | 30~36 | No heat hardening required | Economical pre-hardened plastic die steel. Suitable for high strength die frames and molds for small and medium mass production without surface requirements. | |||

| 01 | =235 | - | HRC46~52 | Can be hardened to HRC46~52. Generally used for mold accessories, laminates, wear-resistant blocks. | ||||

| 45#、50# | 1045-1050 | S45C-S50C | -1.1730 | =235 | - | No heat hardening required | With good machining and machinability, it's suitable for mold plate and mechanical accessories. | |

| 738H | P20 Modified | - | 1.2311 Modified | - | 33~40 | No heat hardening required | (SW318H)--Pre-hardened tempered non-forged steel, large size cross-section hardness uniformity, good welding and thermal conductivity. Suitable for small batch plastic mold production. Not suitable for the molds with Tianjin fire retardant and high corrosion requirements. | |

| 718H | P20 Modified | 1.2738 Modified | 33~40 | No heat hardening required | (SW718H)--Pre-hardened tempered non-forged steel, large size cross-section hardness uniformity, good welding and thermal conductivity. Suitable for small batch plastic mold production. Not suitable for the molds with Tianjin fire retardant and high corrosion requirements. | |||

| LKM | LKM2344ESR | H13 ESR | SKD61 ESR | 1.2344 ESR | =229 | - | HRC48~54 | High purity of steel, uniform structure, excellent toughness and anti-tempering, good fatigue resistance and permeability and good mirror polishing. Suitable for small and medium-sized high surface finish mold without wear resistance requirements. |

| LKM S7M | S7 Modified | 1.2357 Modified | =229 | - | HRC52~58 | After ESR remelting and refining treatment, the steel has high purity, fine microstructure, excellent mirror polishing, sun grain, high wear resistance and good high temperature strength and toughness, and the hardness can reach HRC56-58. Suitable for small and medium-sized long-term production of glass fiber, carbon fiber and other reinforced plastic injection mold. Thermosetting plastic compaction die is also applied to hot stamping die and aluminum alloy extrusion die. | ||

| LKM C1100P | JIS C1100P | Cu copper; High purity, excellent electrical conductivity, easy processing, low deformation. Suitable for precision spark machining electrode. | ||||||

| LKM2083 | 420 | SUS420J2 | 1.2083 | =240 | HRC46~52 | Used in hardened state; good corrosion resistance, wear resistance and polishing properties. Suitable for molds for long-term production of corrosion-resistant plastics. | ||

| LKM2083H | 280~320 | 29~34 | No heat hardening required | Pre-hardened die steel, good corrosion resistance, wear resistance and polishing properties. Suitable for the production of small and medium-sized batch of corrosion resistant plastics. | ||||

| CN2311 | -P20 | -1.2311 | 260~340 | 26~36 | No heat hardening required | Pre-hardened ordinary plastic die steel. Suitable for high strength die frames and molds for small and medium mass production without surface requirements. | ||

| USA MATERION Beryllium Copper Alloy | MOLDMAX HH | UNS C17200 | - | 36~42 | No heat hardening required | High strength beryllium copper alloy, excellent thermal conductivity and high strength, greatly improve injection efficiency and product appearance. Suitable for mold cores and inserts requiring rapid cooling. | ||

New Mold Validation Check List Tool #: ________

| No. | Point to be verified | Yes | No | NA | Comments | ||||

| Processing Info | |||||||||

| 1 | Is Process parameter sheet available? | ||||||||

| 2 | Press screen (temperatures, pressures, injection speed) available? | ||||||||

| 3 | What's the barrel size? | ||||||||

| 4 | What's the melt Temperature of material? | ||||||||

| 5 | What's press Tonage (photo press screen with actual campling force) | ||||||||

| 6 | Is cooling conexion diagram available? | ||||||||

| 7 | Is electrical diagram (book from hot runner supplier) available? | ||||||||

| 8 | Is final part weight vs. Non-pack part weight available? | Final weight : | Non-pack weight: | ||||||

| 9 | Ratio Press (diameter of injection cylinder, how many cylinders?) | Cylinder size: | # cylinders : | ||||||

| 10 | What is the actual neumatic or hidraulic pressure used? (cores press screen) If applicable | ||||||||

| Tooling Info | |||||||||

| 11 | Hardness of materials (cores, cavs, slides). Certificates and physical test at blocks | ||||||||

| 12 | Are cavity block properly identify at tool (engraved at the cav block and at the mold base)? | ||||||||

| 13 | Are all parts properly engraved at mold? (slides, lifters, ejector pins, etc) | ||||||||

| 14 | Are cooling lines properly identify (in-out) ? | ||||||||

| 15 | Is the mold free of water/oil leaks? (verify with air) | ||||||||

| 16 | Does the mold has enough support bar and are properly located? | ||||||||

| 17 | Are the security bar properly located? | ||||||||

| 18 | Does the mold has 2 rings to mold handdling and properly located? (Mold must have thread holes for rings at 2 sides of mold) | ||||||||

| 19 | Has every zone of electrical system being review for proper functioning? | ||||||||

| 20 | Are the parting lines located as per DFM? | ||||||||

| 21 | Is part properly engraved per print? | ||||||||

| 22 | Does the part has date codes as per print and DFM? | ||||||||

| 23 | Is the weight of tool marked at mold? (engraved, paint, stamped) | ||||||||

| 24 | Is general tool size marked at mold? (engraved, paint, stamped) | ||||||||

| 25 | Has every retractil mechanism their own position sensor and conected in serie? | ||||||||

| 26 | Is "top" painted at the top side of the tool? (engraved, paint, stamped) | ||||||||

| 27 | Are the ejector bars same level as tool? | ||||||||

| 28 | Are center ring and nozzle size proper size? | Center ring size: | Nozzle size: | ||||||

| 29 | Is the mold free ofevidence of welding, being packed, noizes or golding? | ||||||||

| 30 | Are the vents properly located and go thru the outside? | ||||||||

| 31 | Is the ejector system layout as agreed per DFM? | ||||||||

| 32 | Is the mold safe enough for handling in the tool room? (Review that the excess in the clamp plate is only that required by setup) | ||||||||

| 33 | Are spare parts from a comercial brand? (Prefered Misumi) | ||||||||

| 34 | Is mold documentation such as 3D and 2D prints available? | ||||||||

| 35 | Is the hot runner documentation avaiable? (2D/3D/sutcase/tools) | ||||||||

| 36 | Are the codes for spare parts available for quick buy? | ||||||||

| 37 | Are spring codes available and do they follow color code? | ||||||||

| 38 | Does mold has cover to protect mold at handdling? (bottom cover) | ||||||||

| 39 | Is final dimensional report and final shot available? (include runner) | ||||||||

| 40 | Verify that all visual characteristics marked at print are present on plastic part. | ||||||||

| 41 | Is the measuring fixture available? | ||||||||

| 42 | Are part gages available? | ||||||||

| 43 | Are mold photos and video available? | ||||||||

| 44 | Is test working properly? | ||||||||

| 45 | Are test photos and video available? | ||||||||

| 46 | Is test documentation such as 3D and 2D prints available? | ||||||||

| 47 | Are actual mold dimensions exactly the same as the 2D and 3D data? | ||||||||