Industrial Equipment

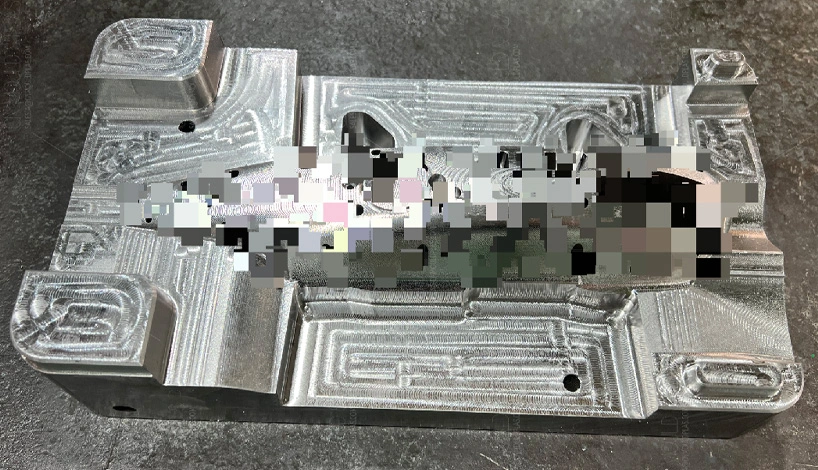

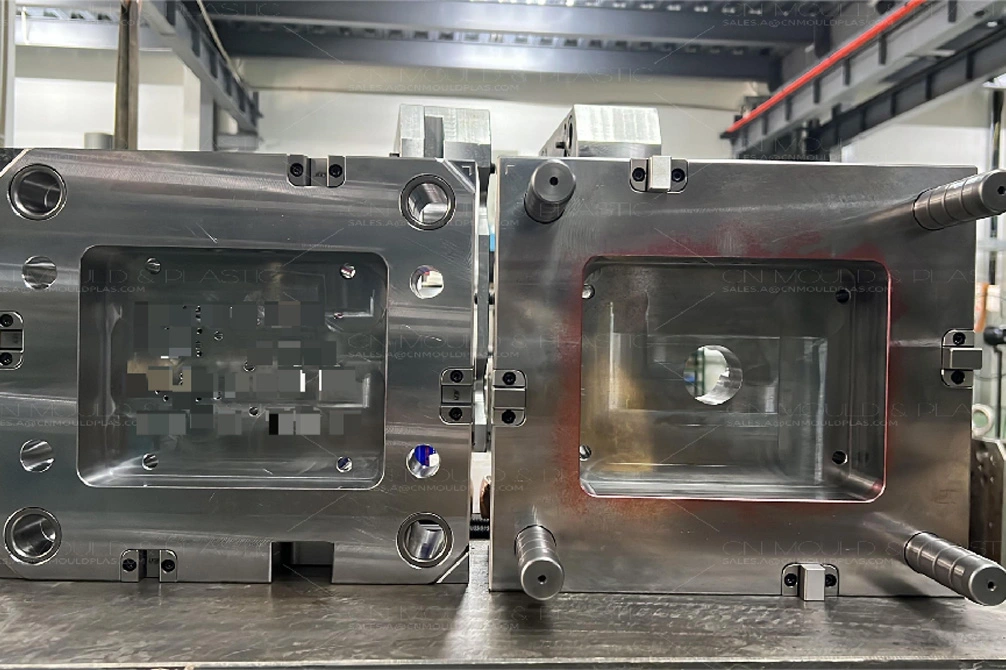

Injection molding products have the characteristics of high precision, light weight and miniaturization. It meets the requirements of industrial equipment parts and has the advantages of good mechanical properties and dimensional stability. Injection molded products are widely used in the fields of logistics, packaging, communications, aerospace, military, machinery, automobiles, consumer electronics and medical equipment to replace some high-precision metal parts.

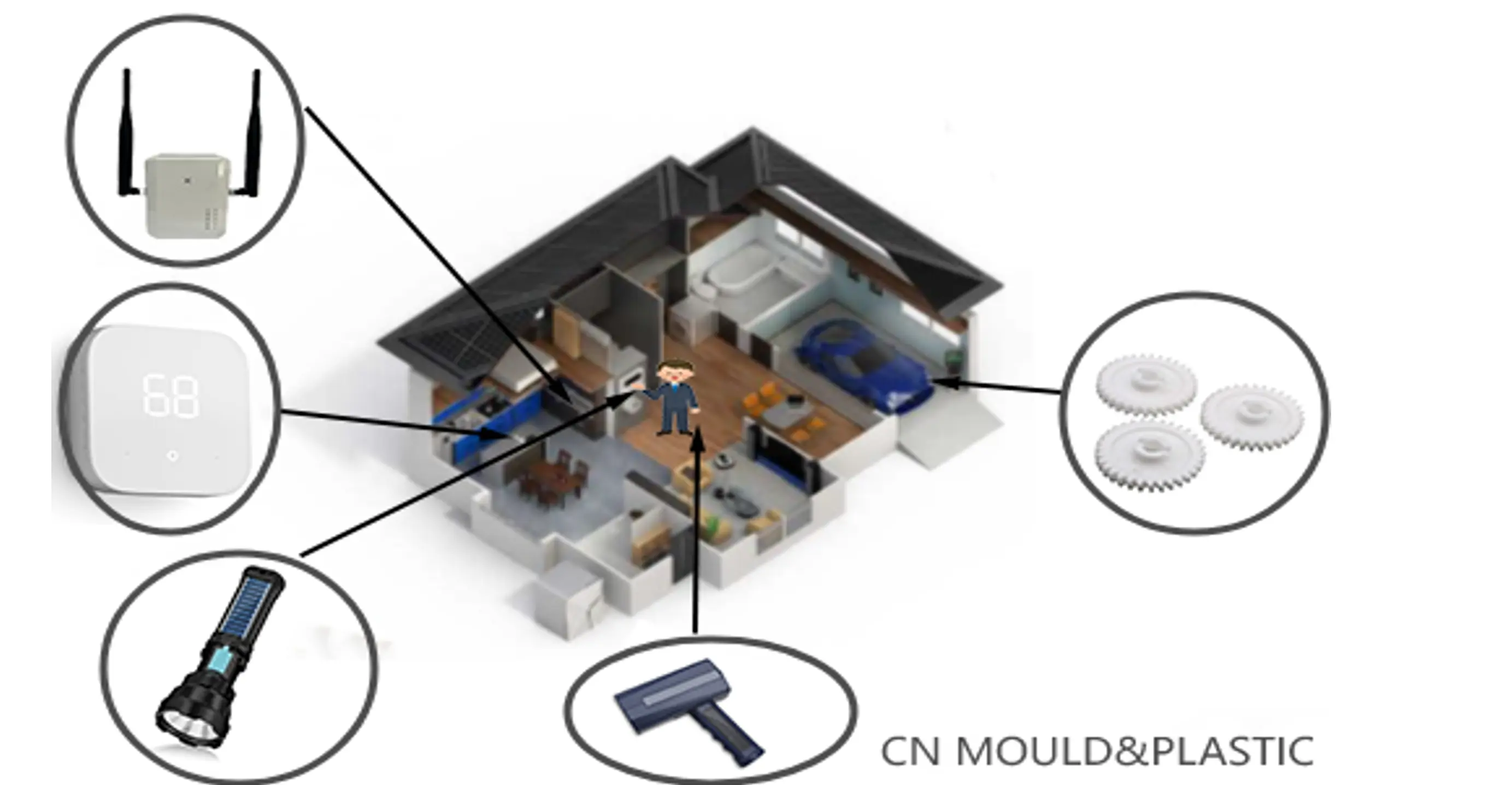

In addition, the injection molding process plays multiple roles in smart home technology. Smart home devices often require housing to protect internal electronic components. The injection molding process can produce housing that provide a strong, durable, and beautifully looking product appearance. Besides, many smart home devices require precision injection molded parts inside, such as brackets, connectors, and protective covers for electronic components. These components require a high degree of precision to ensure the proper operation of the equipment.