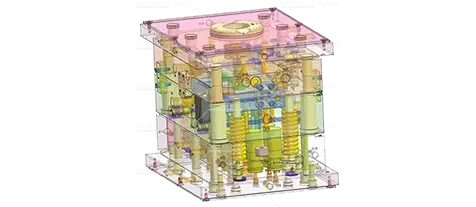

Hot Runner System is an injection mold technology that uses heat to keep the plastic in the runner in a molten state. In a hot runner system, heating rods and tube heaters are set near or in the center of the runner and gate to ensure that the entire runner from the injection molding machine nozzle to the gate is in a high temperature state. In this way, after each injection molding, the plastics in the runner do not need to be removed because they remain molten. When starting the machine again, simply heat the runner to the appropriate temperature.

The hot runner system mainly consists of nozzle, manifold, temperature controller and other components. Nozzles are divided into open nozzle and valve nozzle, and different types of nozzles determine the choice of hot runner system and the manufacturing method of the mold. Hot runner technology is widely used in various injection moulds and plays an important role in improving the quality and efficiency of plastic products

1. Open hot runner

The open hot runner has a simple structure, which is suitable for semi hot runner, but not for fully hot runner. Fully hot runner has a high limitation on materials, and directly contacts the product surface, which is prone to wire drawing and leakage, and the surface quality is poor.

Semi hot runner does not touch the product but touches the tiny runner, so it can use the open hot nozzle, which is widely used in foreign high-precision molds.

2. Valve hot runner

Valve hot runner saves materials and creates high quality plastic surfaces while maintaining a tight internal quality and high strength. There are two main categories of valve hot runners in the world (based on injection principle) : cylinder type and spring type. Cylinder type mainly has the following brands: DME (United States), INCOE (United States), MOLD-MASTER (Canada), HUSKY (Canada), AKOMA (China) and so on. Because of its structural characteristics, the cylinder type determines that the mold accuracy is high, and the debugging and maintenance are more complex. The spring type relies on the balance of the spring and injection pressure to control the valve switch. The assembly, debugging and maintenance are simple, and the mold accuracy is not high. The main brand of spring type valve hot runner is FISA (Japan).

The wide application of hot runner technology is a major change of plastic mold. In injection molding, it has quite a number of unparalleled advantages, it can be said that with the further development of its technology and the reduction of manufacturing costs, hot runner technology will become more and more popular. To formulate national standards for hot runner components, actively produce cheap and high-quality components, and do a good job of publicity and promotion of hot runner technology are the key to the development of hot runner molds.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk