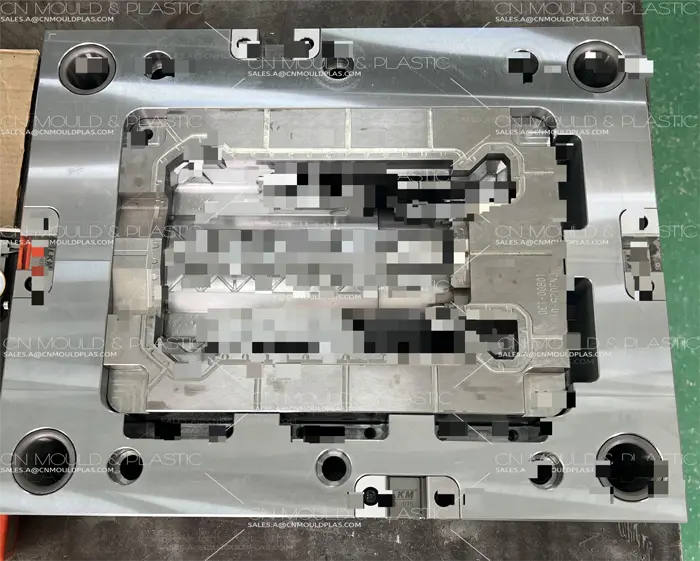

Let's use a Four Shot Molding component as an example:

Think about creating a soft-touch plastic part with a clear window, a crimson top layer, and a black bottom. Four Shot Molding may be used to achieve this in a single cycle.

The first shot during the 4k Injection Moulding procedure will form the base of the component by injecting black plastic into the mold cavity. Red plastic will be injected in the second shot on top of the black foundation to produce the top layer. A third injection will inject transparent plastic for constructing the window. A soft-touch material will ultimately be injected into the part's grip region in the fourth shot.

As a consequence, a complex item consisting of several materials and colors that would be difficult or impossible to build using traditional production methods is produced in a single cycle.

The automotive, consumer electronics, and medical equipment industries, among others, commonly require components with diverse materials and colors, might all benefit from using these four-shot molded parts.

The main difference between Four Shot Molding and Three Shot Molding is the number of materials or colors that could be utilized in a single production cycle.

While up to three materials or colors could be utilized during a single cycle of Three Shot Molding, a single cycle of Four Shot Molding can employ up to four different materials or colors by gradually injecting each one. This indicates that Four Shot Molding, as compare to Three Shot Molding, may produce things with more complex designs or components.

Four Shot Molding often requires a larger and more advanced injection molding equipment than Three Shot Molding because of the additional injection units needed. As a result, Four Shot Molding might become costly and hard to set up and operate.

The specifics of the manufacturing process, such as the part's design, the materials and colors that need to be utilized, and the desired production volume, will determine whether to employ the Four Shot Molding or Three Shot Molding molding technique in the end.

Four Shot Molding is a complex and challenging manufacturing process that could present a number of challenges. The following are some common challenges with four shot molding:

Overall, despite the fact that 4k Injection Molding offers significant benefits in the manufacturing of complex plastic components including several materials or colors, there are a number of challenges that need to be resolved.

Four Shot Molding provides a lot of advantages and may be used to produce plastic parts that need various materials or colors.

1. Flexible Design: Four Shot Molding allows for the creation of sophisticated products with several parts or colors in a single cycle, increasing flexibility in design. Because of this, designers may create more sophisticated and cutting-edge designs that could prove challenging or impossible to execute using other production procedures.

2. Enhanced Manufacturing Productivity: Four Shot Molding can improve manufacturing productivity by producing parts in a single cycle that feature a variety of materials or colors. Fewer assembly or painting procedures are consequently needed, which can speed up production and save costs.

3. Lessened Waste: Four Shot Molding can minimize waste by cutting the number of materials needed to make a final product. This is because it is possible to precisely target the materials to specific sections of the part, which reduces waste and excess material.

4. Improved Product Quality: Four Shot Molding may create components that are stronger, more practical, and longer-lasting by combining several materials. Making industrial or automotive items that must endure tough circumstances can benefit especially from this.

Four Shot Molding has a number of advantages when making plastic parts that need to be manufactured of various materials or colors, including flexible design, increased production efficiency, lower waste, and improved product quality.

Multiple materials or colors may be used in a single mold through a plastic injection molding method called Four Shot Molding.

Thermoplastics such as PP, PC, and ABS, Thermoplastic elastomers like TPEs, TPU and TPV, silicone, metals and other additional materials.

The lead times for four shot molding projects can vary depending on factors such as part complexity, mold design, material availability, and production volume. It is advisable to consult with the manufacturing supplier to get an accurate estimate for your specific project.

During four shot molding, quality control measures are implemented to ensure the accuracy and consistency of the produced parts. This includes regular inspections, dimensional checks, and material testing to verify that the parts meet the required specifications and standards.