Drone & Camera

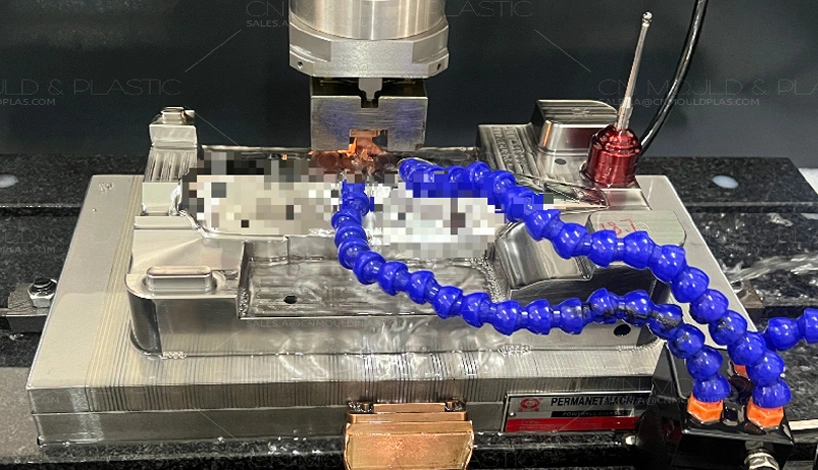

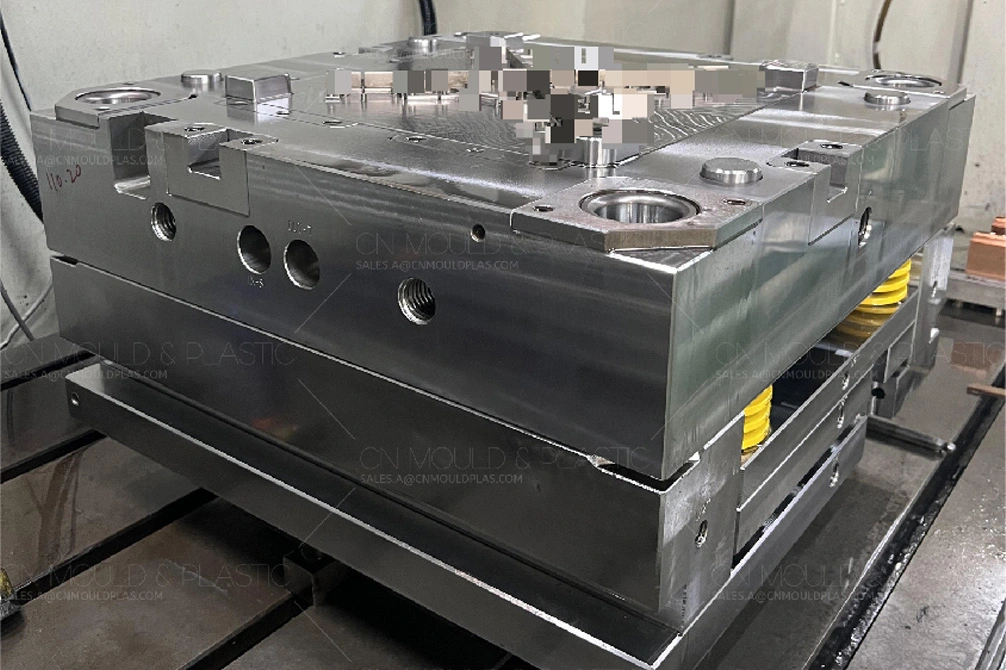

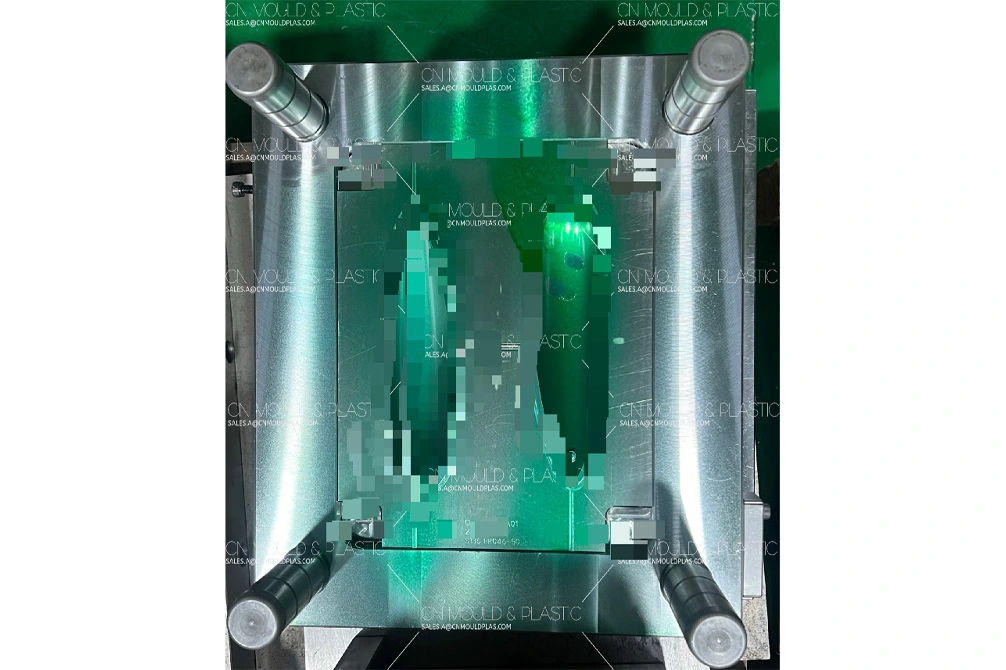

Injection mold is one of the important tools for making digital camera shell. The injection mold skillfully combines design technology and production practice to meet the needs of producing high-quality enclosures. Injection mold design mainly includes mold structure design, mold material selection, mold parts processing and other work. Excellent injection mold design can greatly improve the processing efficiency of the shell, reduce production costs and defective product rate.

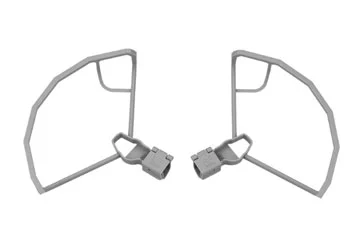

The body, propeller, propeller protector, landing gear and other components of drone can use engineering plastics, in addition to cost savings, there are advantages that metal does not have. Compared with traditional metal materials, composite materials have the characteristics of high strength and rigidity, low thermal expansion coefficient, strong fatigue resistance and vibration resistance, and can reduce the weight of 25%-30% when it is applied to the drone’s structure.