1. Have a good knowledge of the technical requirements of the product parts; determine the optimal design scheme of the fixture

After receiving the design task, it is necessary to prepare the data required for the design of fixture, including parts design drawings and technical requirements, process regulations and process drawings, and relevant processing equipment. After understanding the technical requirements of the basic structure, dimensional accuracy, form and position tolerance of the product parts, it is necessary to find out the key and important dimensions of the parts (the size must be guaranteed), and then basically determine the design scheme of the fixture.

2. Determine the positioning reference on the fixture

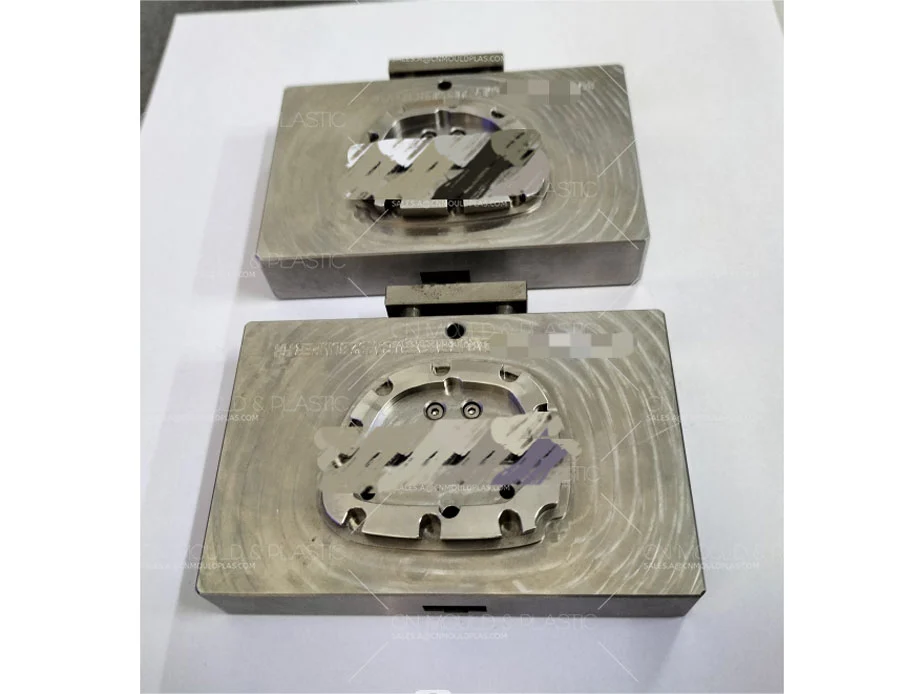

For each set of fixture design, the key and important part of the parts should be as the positioning part on the fixture (positioning design). Also should determine the ideal positioning design (precision design), the main positioning reference (first reference) and secondary positioning reference (second reference).

3. Clamping of parts and clamping structure design of the fixture

Clamping is needed after positioning in work fixtur, so that parts in the process of processing can maintain the positioning to avoid any damage. During the processing of parts, displacement, deformation and vibration will occur, which will affect the processing quality of parts.

4. The precision accuracy of fixture

The primary purpose of commonly used fixture is to ensure the processing quality of parts, specifically, when using fixture processing, it is necessary to ensure the size (shape) accuracy and position accuracy of parts.

5. Draw the fixture

The general drawing of the fixture should be drawn in accordance with the results of the final discussion (three-base system method). The processed parts should be marked with double dot lines, the title bar should be filled in correctly, and the standard parts should be marked with their specifications and standard numbers. Also in accordance with the commonly used match and accuracy of the fixture, the precision of the positioning and guiding components, the combination of the main parts to specify the appropriate dimensional tolerances, other position tolerances should meet the reasonable requirements of the tolerance values. Finally, other dimensions are indicated, including overall dimensions, connection dimensions and important fit dimensions.

Choose CN Mould, a professional fixture design company, for innovative solutions and expert service that enhance your project efficiency!

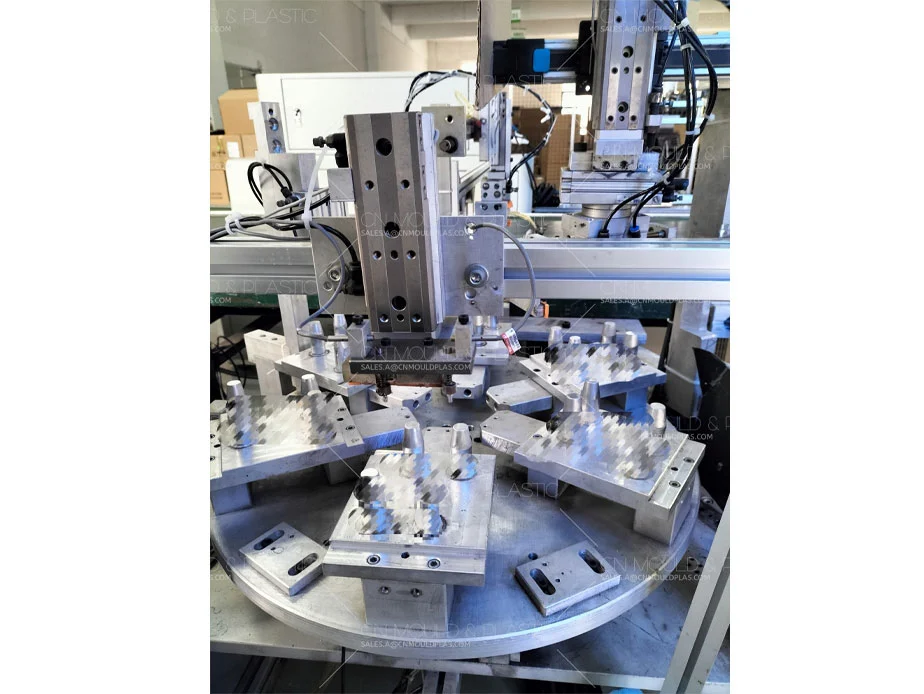

Fixtures also play a vital role in the molding and post-processing. They are used throughout the production process, especially in the middle and later stages:

Functional testing: Fixtures hold the mold components in place while they are tested to ensure they operate as intended.

Auxiliary assembly: They assist in assembling specific parts of the mold, maintaining precise dimensions and alignments.