The extra layer of insulation offers improved shielding for the cable, safeguarding it against wear and tear, as well as damage from impacts.

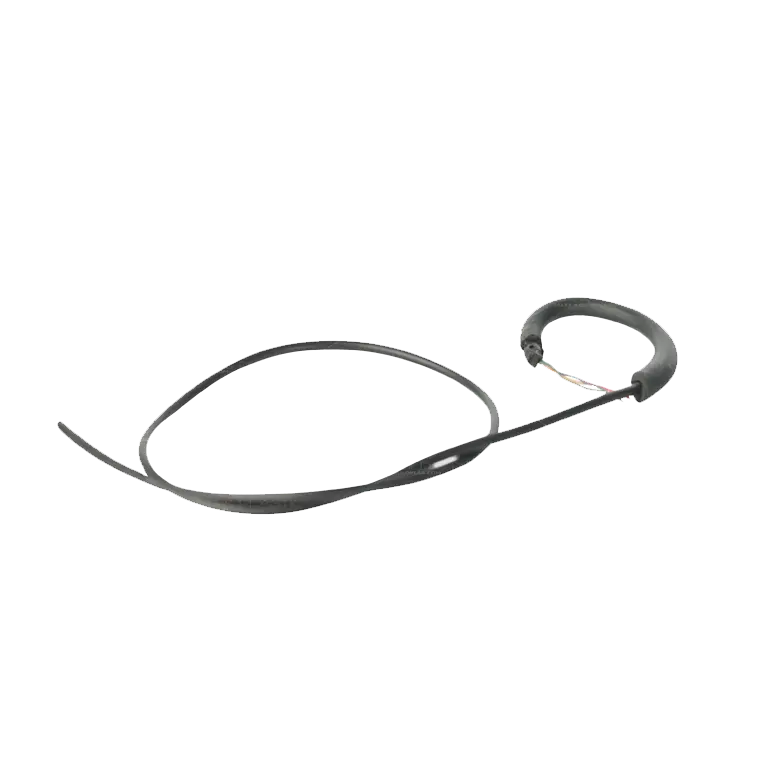

Overmolding fills the space around internal components of the cable, which prevents them from moving or shifting inside the cable. This makes the cable less vulnerable to tampering compared to regular cables.

The ability of overmolded cables to flex within a certain range without compromising their durability and functionality.

Using overmolding can remove the need for clamps or fixtures, making it possible to assemble cable quickly and safely.

Overmolding allows for the tidy organization and management of cables. The solid-colored housing of the cables aids in systematic cable management.

1. Make sure the cable surface is clean prior to injection molding.

2. Under the premise of filling a product, combined with a scientific trial mold method, it is best to steer clear of excessive injection speed and pressure.

3. Ensure that the mold temperature and material temperature are set at appropriate levels to avoid any deformation of the cable.

4. After the molding process is complete, it is important to promptly transfer the finished products to prevent them from accumulating and tangling, which can make them difficult to separate.