Automotive

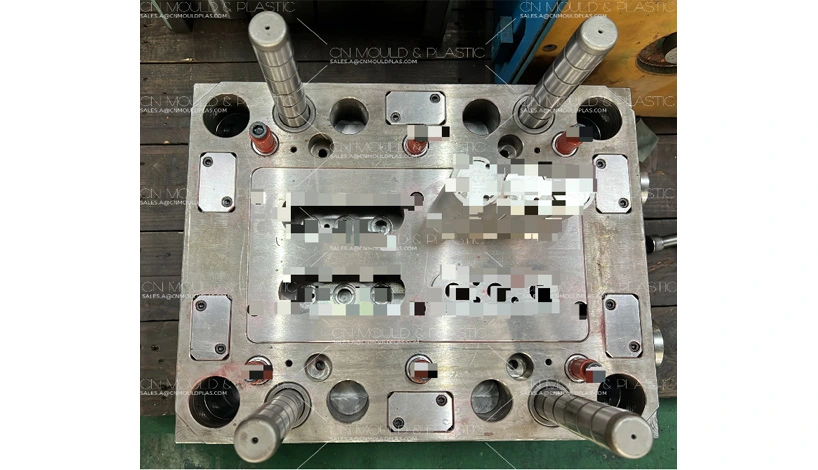

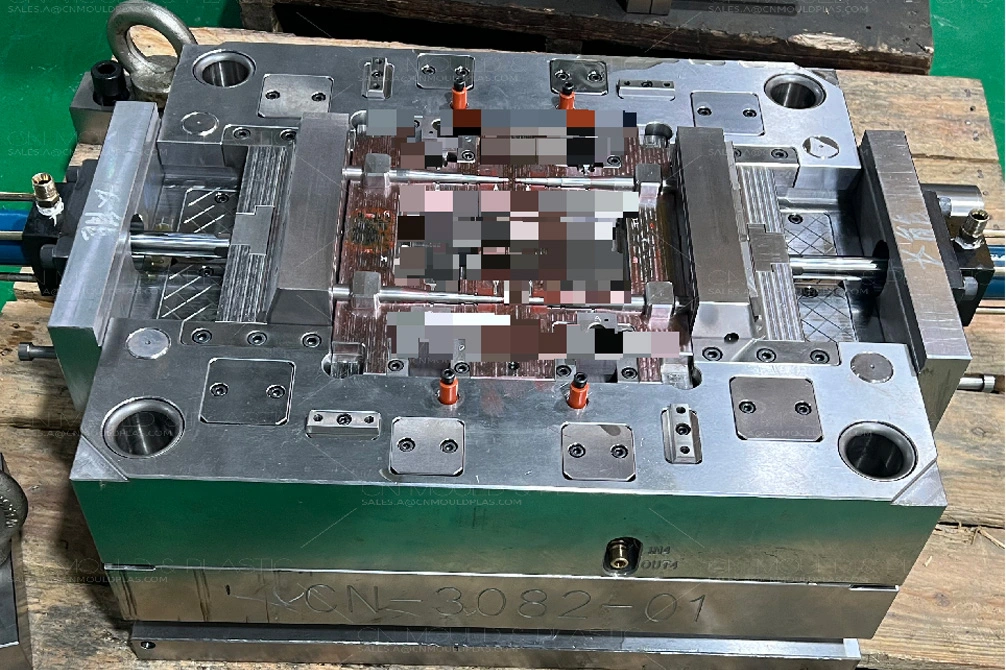

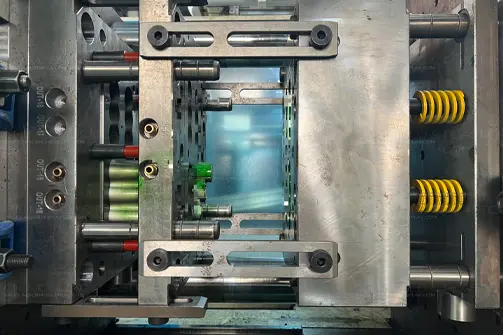

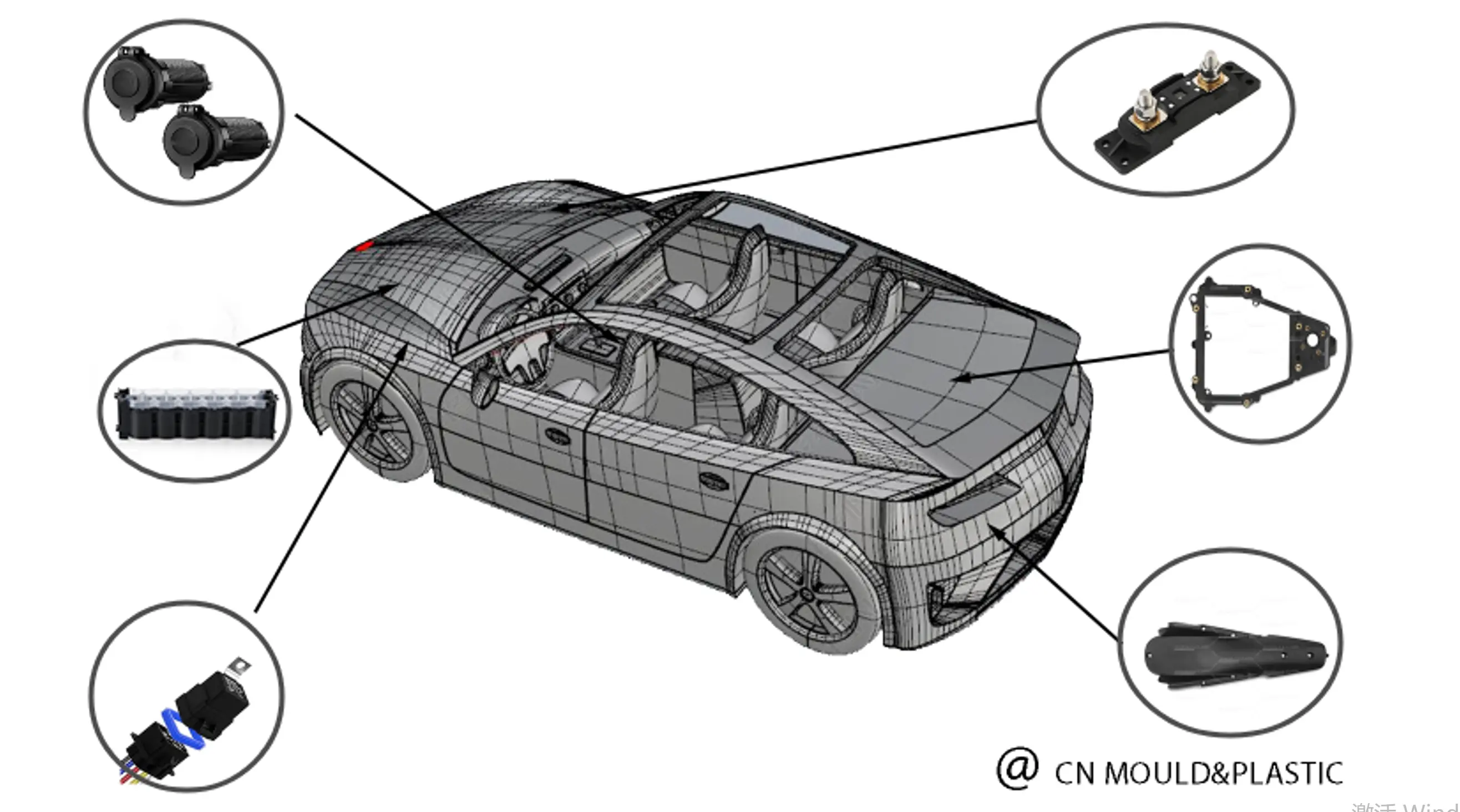

Injection Molding technology plays an important role in the manufacture of automotive exterior parts. Injection Molding technology has the advantages of high production efficiency, low cost, short production cycle and can meet the requirements of quality and quantity of automotive appearance parts such as car bumper, lamp shell, window frame and other parts.

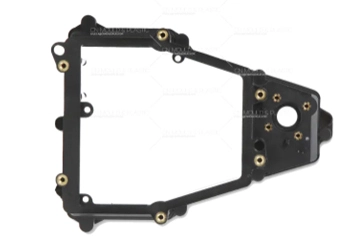

Injection Molding technology is also widely used in the manufacturing of automotive functional parts. Automobile functional parts mainly include instrument panel, seat accessories, air conditioning outlet and so on.

Injection Molding technology can meet the dimensional accuracy, strength requirements and complex shape manufacturing needs of these parts.

Injection Molding technology can also be used to make automotive interior parts. Automotive interior parts include instrument panels, door panels, center console, which have an important impact on the comfort and aesthetics of the car. Injection Molding technology can produce interior parts with complex structures and various shapes, and can achieve color transformation in the production process. This makes the interior design of the car more diverse and meets the needs of different consumers.