In summary, angled pins insert molding is primarily used to enhance the mechanical strength and stability of a molded part through the use of angled pins. This method guarantees the dependability and stability of the part.

Angled pins insert molding process is widely used in various industries such as automotive, medical, and electronics. Especially connectors with angled pins, which are important parts that are required in the automobile industry and other industries.

Furthermore, angled pins are metallic components utilized in connectors for achieving conductive transmission.

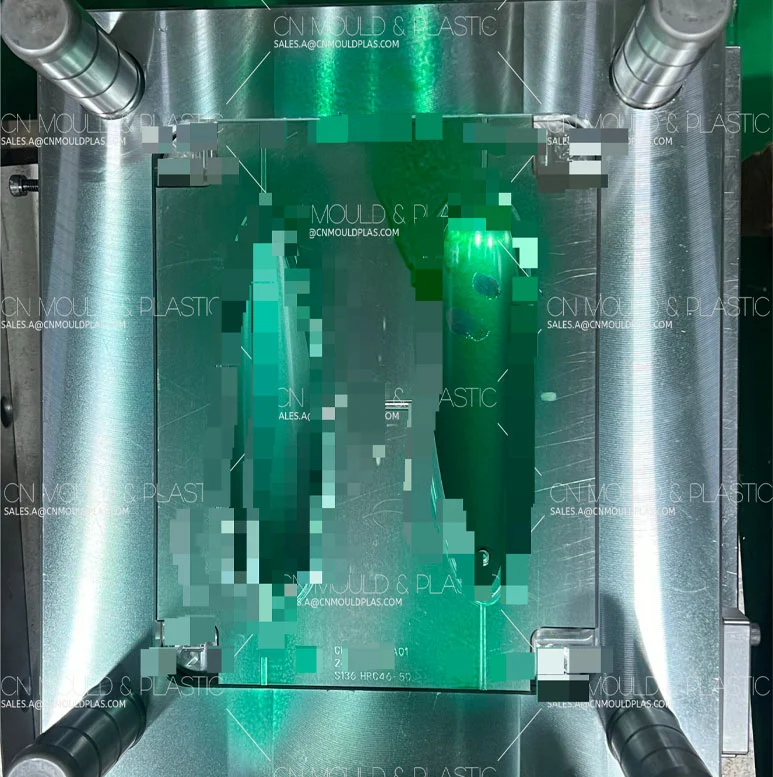

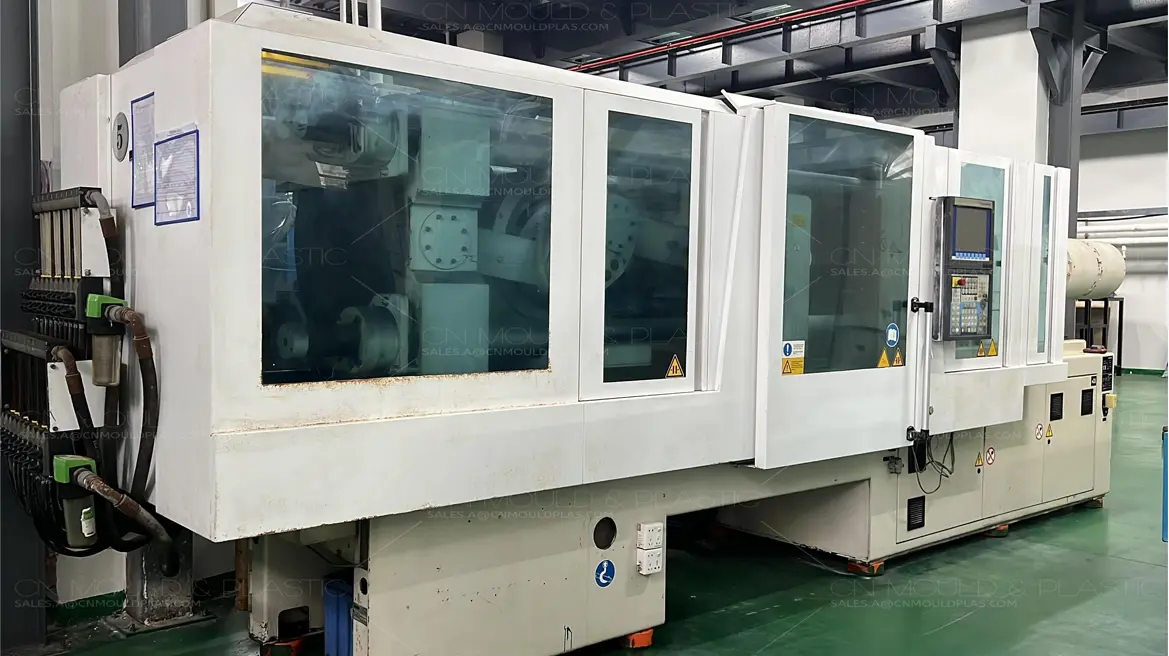

CN Mould specializes in insert molding and Overmolding, with a strong focus on mold structure innovation, effective problem solving, and clear communication.

As a result, we have extensive experience in angled pins connector housing.