Waterproof connector is a special connector designed to maintain the normal operation of electrical equipment in the presence of moisture in the environment, they are usually composed of water-resistant materials and sealed structures, can effectively prevent moisture, moisture and dust into the connector interior, thereby protecting the connector and connected electrical equipment from moisture damage. The main features of the waterproof connector include:

The waterproof performance of waterproof connectors is primarily assessed by the International Protection (IP) rating, which defines the dust and water resistance of the connector. For example, IP68 is the highest rating, indicating that the connector is completely protected from dust and is continuously submerged under a certain pressure.

These connectors are widely used in industry, automobile manufacturing, medical equipment, construction, ship maintenance and other fields, especially in outdoor, wet, high temperature, low temperature, vibration, corrosion, UV and other harsh environments.

Waterproof connectors usually adopt a special sealing design, including the use of O-ring seals, clamp seals, injection seals, etc., to ensure the waterproof effect in various application scenarios.

Below we do tests of the connector in the above figure to analyze its waterproof level:

IP X5 Test

Actual test circumstances:

Using water with a flow rate of 12.5L/min, spray the product housing and the test time is more than 3 minutes.

Results:

The waterproof connector can maintain normal operation in the case of jet water.

Comments:

The IPX5 aterproof ratingindicates that the connector can withstand the effects of low pressure water flow.

IPX7 Test

Actual test circumstances:

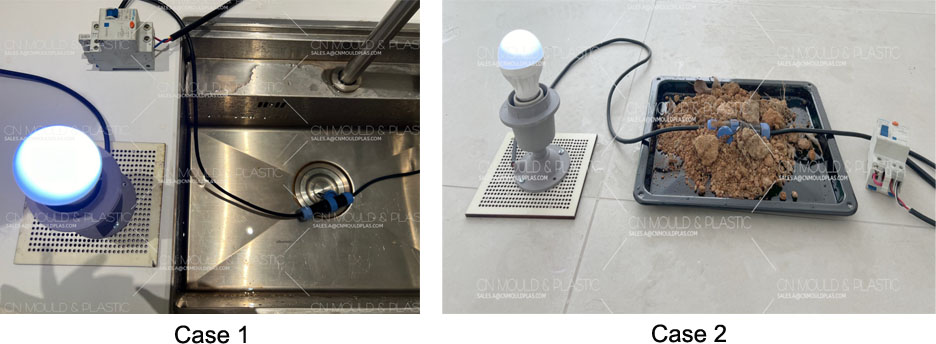

Case 1: Soak the connector in salt water for 30 minutes.

Case 2: Soak the connector in soil for 30 minutes.

Results:

Case 1: During the test, moisture did not enter the product. At the end of the test, the product can work normally and without damage, and meets the IPX7 waterproof class standard.

Case 2: After the connector is soaked in soil for 30 minutes, it is not corroded by soil and can maintain normal working condition.

Comments:

The IPX7 waterproof rating reveals that the connector has a strong waterproof function, and even if submerged in water under specified conditions, moisture will not enter the interior.

IPX9 Test

Actual test circumstances:

Place the connector in the salt spray machine for 30 minutes.

Results:

The connector maintain normal use function, no rust.

Comments:

IPX9 rating is mainly used to test whether electronic devices can work properly under high pressure water spray and whether they can withstand a large amount of water shock. The IPX9 waterproof rating is the highest of all IPX ratings.

In general, waterproof connectors play an integral role in a variety of industrial applications that may be exposed to moisture and wet environments due to their excellent water and dust resistance.