Over 20 years, CN Mould & Plastic focus on making injection mold and develop an expertise of Elastomers. Tens of Millions of parts are shipped out each year to world-class customer such as HP, DELL, Apple.

Over 20 years, CN Mould & Plastic focus on making injection mold and develop an expertise of Elastomers. Tens of Millions of parts are shipped out each year to world-class customer such as HP, DELL, Apple.

Rich experience in injection molding and design flexibility for insert molding enable CN to quickly comprehend your need, cooperate with you to develop and improve products, and satisfy your customized requirements.

CN is certified by ISO 9001:2015 and ATF 16949:2016 discipline issued by the International Organization for Standardization (SGS) for Quality Management. Besides, we have a systematic program for handling complaints.

Once we receive the customer's order, we will arrange the production as soon as possible.

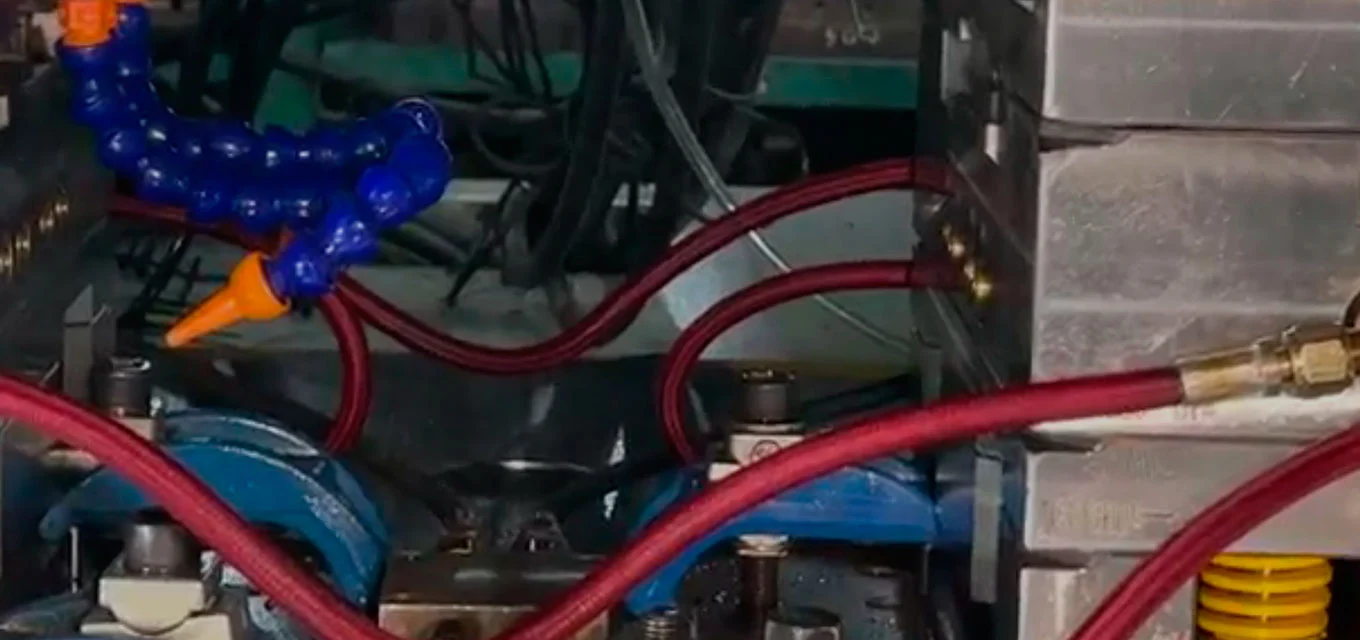

Our production philosophy is to achieve machine automation as much as possible, putting efficiency and quality in an important position to ensure timely delivery.

If you need a high-quality, complex product, custom insert molding is the most efficient method that bonds effectively between plastic and inserts made from other materials. In particular, this process is ideally suited for the production of parts with extremely tiny tolerances and mass production.

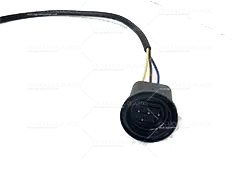

Because of this, insert molding technology has found increasing use in industries such as automotive, medicine, and consumer electronics in recent years. SIM card holders, connectors, charger housings, electrical wire connectors, and so on are all examples of common products made with insert molding services.

Material: Silicone +PC

Insert Molding

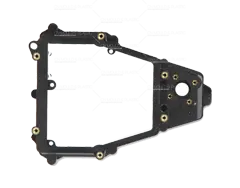

Material: PBT+30GF

Insert Molding with Angled Pins

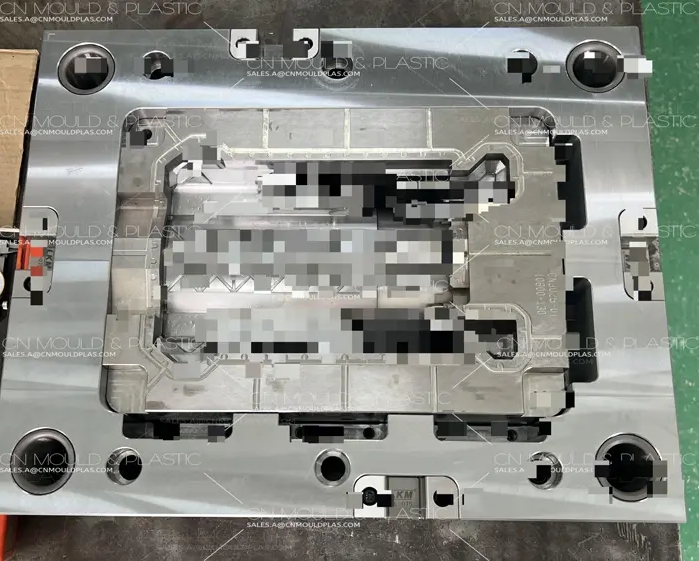

Material: Nylon+14GF

Insert Molding

To precisely manufacture a plastic product via the injection molding process, a very tight tolerance is required. The molding process can fail even if there is only a tiny difference. Therefore, it is essential to know the shrinkage rate of the injecting material. Injecting materials for CN are usually chosen from nylon, PBT, and PPS.

Materials for the insert need to be able to sustain the pressure of the injection molding process without being deformed; thus, metal, plastic, silicone, magnet, cable are all appropriate insert materials. In CN Mould, one of the leading insert molding manufacturers, the insert molding process is widely applied to automotive accessories and electronic components, such as connector housing, charger housing, SIM card holders, cable components, etc. Therefore, metal is the most common material for inserts, for example, copper brass part, stamped part, angled pin, pogo pin. Of course, there are some special materials, like PCB.

Insert molding technology combines plastic with other different materials to form a single product. This may include combinations of plastic and metal, plastic and stamped insert, plastic and magnet, and so on.

1. Increase Design Flexibility.

2. Reduces Assembly and Labor Costs.

3. Increases Reliability.

4. Reduces Size and Weight.

1. When using prefabricated substrates.

2. If the substrate contains metal, cable, stamped part, or PCB.

1. Limiting tests for the part's shape and dimensional accuracy is crucial due to the inconsistent shrinkage rates of the materials during the insert molding process.

2. Inserts can be deformed and shifted during the injecting process; therefore, it is necessary to fully take into account the shape of products and the position of inserts when designing the mold.

3. Predicting gate location and molding cycle in advance is required.

4. Confirming whether the insert requires pre-heating or drying treatment is necessary for ensuring both the quality of the finished product and the stability of the molding process.