ELECTRICITY CONDUCTION

ELECTRICITY CONDUCTION  LIGHT EFFECT

LIGHT EFFECT  HIGH TEMPERATURE SEALING

HIGH TEMPERATURE SEALING

Insert Molding guarantees tight tolerances and superior strength.This automotive housing for automotive applications features a cutting-edge metal insert molding process developed at CN Mould & Plastic. For years, we've been dedicated to providing trusted components that stand the test of time.

Silicone's inherent water resistance and easy cleaning make it the perfect choice for active lifestyles. Engineered using an advanced LSR molding, these bands deliver exceptional comfort and durability at an accessible price point. Explore our diverse range of silicone products, like stunning overmolded jewelry, and discover how this remarkable material can enhance your life, seamlessly blending practicality with timeless design.

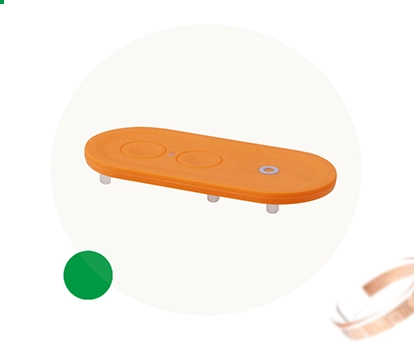

Overmolding technology offers significant benefits compared to traditional injection molding methods. Their lightweight design enhances portability and user comfort, while superior aesthetics elevate the perceived value and visual appeal of your gadgets. Additionally, overmolding allows for increased personalization, enabling you to incorporate unique features and branding elements. This versatile technique finds applications across various industrial sectors, ensuring optimal performance and user satisfaction in diverse settings.

Earphones injected using cable overmolding boast exceptional resilience. This innovative technique seamlessly bonds the cable to the earphone body, creating a fortified connection that resists shocks and repeated bending. Unlike traditional assembly methods, overmolding eliminates weak points, preventing damage and ensuring long-lasting performance.

Embrace gentleness and reliability with Low Pressure Molding (LPM), an efficient solution for protecting delicate electronics. Unlike traditional injection molding, LPM utilizes low-pressure and low-heat polyamide hot melt adhesives. This makes it ideal for overmolding sensitive components like printed circuit boards (PCBs), batteries, and connectors, safeguarding them from stress and damage. Additionally, LPM excels at sealing these components, creating a watertight and dustproof barrier. LPM also shines in relieving strain on wiring harnesses and cables, preventing wear and tear for enhanced durability. In essence, LPM offers a gentle yet highly effective way to package, seal, and protect your valuable electronics.

Two decades of focus, fueled by a passion for progress. For nearly 20 years, CN Mould & Plastics has honed its expertise in injection molding and mold production. But we don't rest on our laurels. We constantly explore and implement solutions that boost efficiency and productivity, pushing the boundaries of what's possible.

Our growth is powered by collaboration. We recognize the invaluable contributions of our teammates, clients, and business partners. Their trust and support fuel our unwavering commitment to always move forward, always improve.

We offer a comprehensive range of manufacturing processes for all your plastic needs, from classic techniques like injection molding and die cutting to advanced options like LSR molding and four-shot molding. With such a wide array of equipment at our disposal, you can explore various manufacturing possibilities, accelerate project timelines, and streamline your supply chain.

But that's not all! We also provide a multitude of post-processing services to add the perfect finishing touch to your products. Choose from pad printing, UV coating, laser marking, ultrasonic welding, gold stamping, laser cutting, multi-color printing, and ultrasonic welding for intricate shapes and thin-walled products.

Whether you're seeking traditional methods or cutting-edge solutions, we have the expertise and resources to bring your plastic vision to life. Let us help you expand your possibilities and simplify your journey!